Introduction

This case study describes an Airius wirless sensor proof-of-concept test performed on a Krofta pump at a Paper Mill in Massachusetts, USA.

Airius sensors (10-1000Hz) were installed on two Krofta pumps (DE) September 2019. In November 2019, damage on the bearing outer ring was detected.

Mill information

The paper mill specialized in Speciality Papers – Activated Carbon Filter Paper, Desiccant Paper.

Capabilities

Celulose pulps, Cotton, Aramid and Carbon fibers

Mill at a glance

- Two paper machines

- Products: Decrotive surfaces, overlay papers, solid core papers, core and backer

- Mill was built in 1806

- End users – fine arts, automotive, medical and activated carbon for filtration.

Conclusion and summary

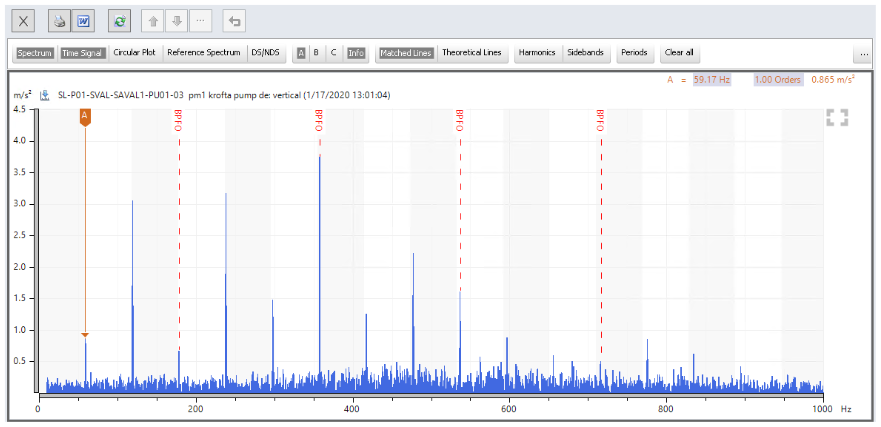

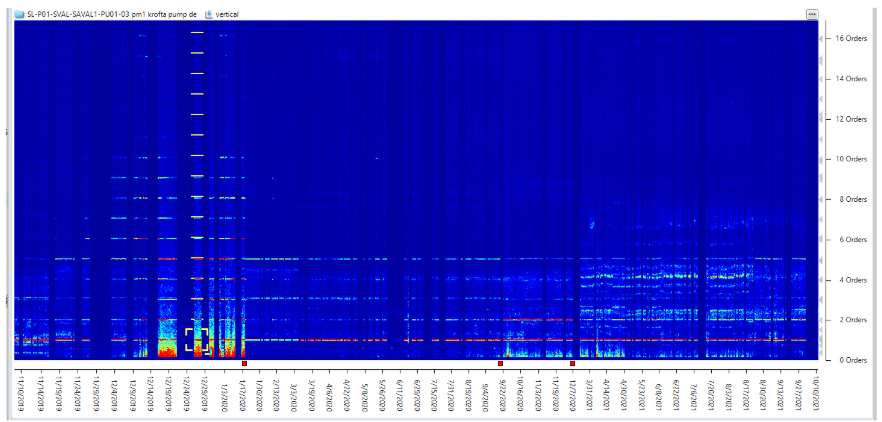

An increase in RMS values early November through mid-December 2019 on Krofta pump #1, DE bearing and the review of both FFT and Colored spectrum clearly shows BPFO. A bearing replacement was schedule on the next shut-down January 18, 2020.

Application description

Selectifier Screen removes stock lumps or fiber bundles from the furnish. As the rotor turns, the paddles the stock is pushed out towards a slotted basket. From there, the acceptable stock moves through the slots and continues towards the headbox, then onto the wire. The unacceptable stock drops to the bottom where it is then sent to the sewer.

Krofta pump

This pump is used within our white water reuse process. Water with fine solids is pumped by this pump to tank where the fiber solids are recovered, and either sent back to the process or to the sewer.

Background

The Paper Mill has been an SPM user since 2007, with the then Leonova Infinity, which is utilized for trouble-shooting bearing problems on motors and pumps. Due to the success of increased performance and reliability as a result of condition monitoring, they decided to upgrade to the Leonova Diamond in October 2014. The mill then looked at remote monitoring options for the Krofta pumps due to accessibility issues with the portable instrument. SPM Airius was selected over KCF wireless sensors. SPM Condmaster Ruby 2029 database at this Mill consists of 1113 measuring points. The objective is to convert at least half of these points to online.

System setup

The #2 Krofta pumps were installed with one Airius sensor on each DE of the pump.

The following parameters were used in the system setup:

Vibration:

- Short time memory: Time signal and FFT

- Long time memory: Time signal and FFT

- Upper frequency: 1000 Hz

- Lines in Spectrum: 1600 lines

Case description Support Documentation

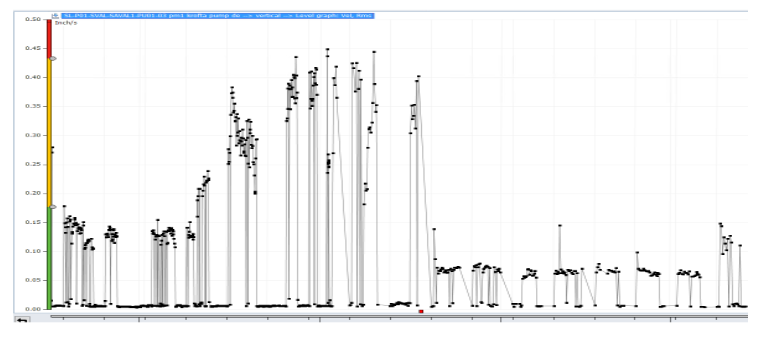

In November 2019, an increase in RMS values indicated early stage bearing damage by December 2019. RMS values had increased enough to justify a bearing replacement. FFT and Colored spectrum graphs clearly show outer ring damage on Krofta pump #1. In January 2020, the bearing on Krofta pump #1 DE was replaced as clearly seen in all graphs.

Fig 7. Krofta pump #1 RMS trend

Fig 8. Krofta pump #1 FFT with BPFO

Fig 9. Krofta pump #1 Colored Spectrum with BPFO

Conclusion

After a successful proof-of-concept, the Paper Mill has been purchasing Airius sensors for all inaccessible locations, and will start a proof-of-concept with ENCEN16 on a low speed gearbox 4th quarter 2021.