Introduction

This case study describes bearing damage detected through online measurements taken from a ball mill at the flotation plant of Asarel Medet AD in Bulgaria. Asarel Medet AD is among the largest Bulgarian mining companies for the extraction and enrichment of copper ores, located in the territory of Panagyurishte in the Pazardzhik district. The company is recovering and processing about 13 million tons of copper ore annually, producing and exporting copper concentrates and cathode copper. SPM HD is a well-proven technology within Asarel Medet AD since it provides very early pre-warning time and helps for accurate planning of maintenance activities and machine stoppages.

Conclusion and summary

The customer has an Intellinova online system, mainly Intellinova Standard, comprising twenty-seven Commander Units which monitor 570 measuring points on critical machines in the open pit mine and flotation plant. The equipment in the mine consists mostly of conveyor belts (electrical motors, gearboxes, and rolls) and in the flotation plant of ball mills, autogenous mills, and flotation machines (electrical motors and gearboxes).

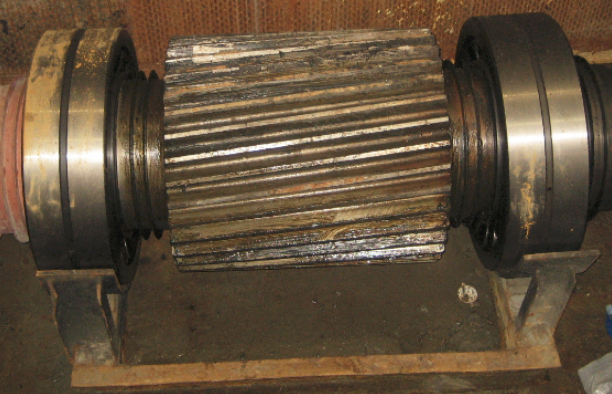

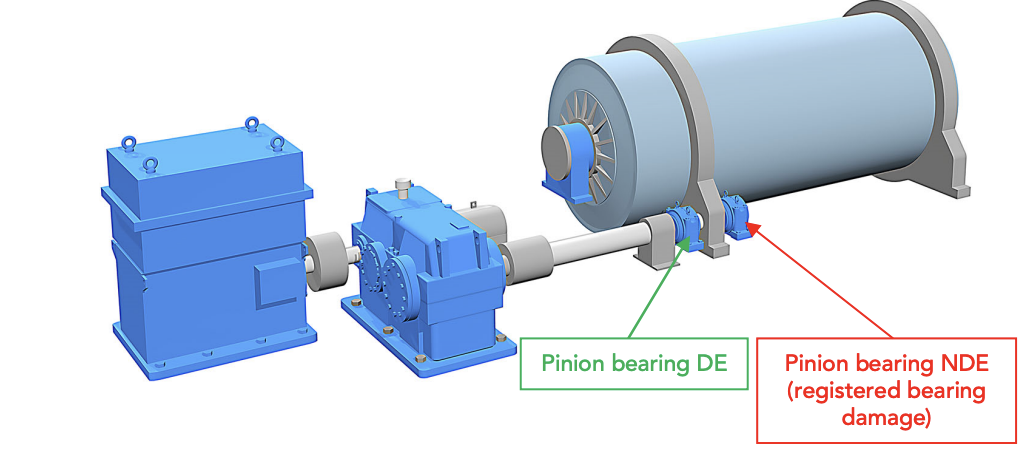

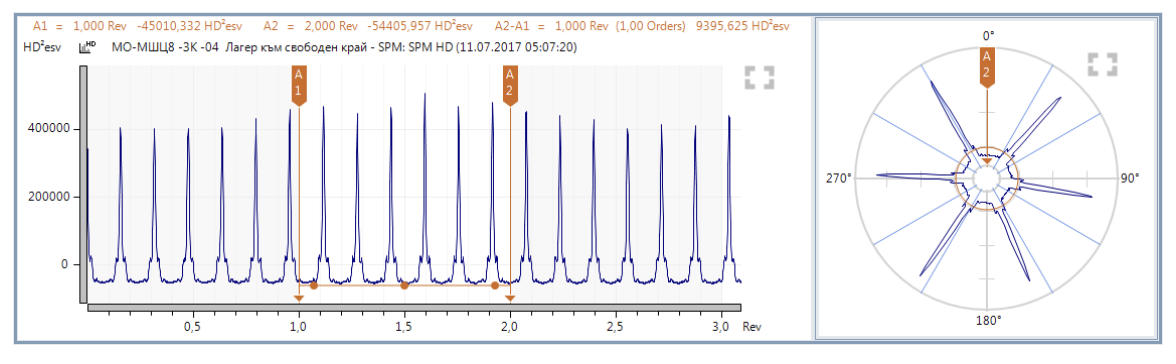

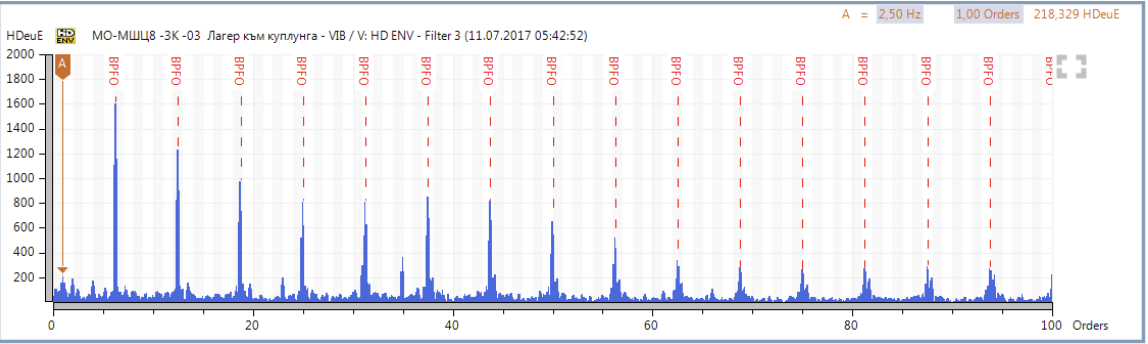

The subject of this case study is the NDE (non-drive end) Pinion Bearing of Ball Mill No 8 in the Mill Dpt. in the flotation plant. The bearings on the pinion are of type 22380YMB. SPM HD Spectrum from the NDE bearing shows a clear match of the BPFO (Ball Pass Frequency Outer Race) symptom. According to the customer, following the indications for bearing damage from Condmaster Ruby they replaced the pinion shaft, where they found visible signs of outer race damage on the NDE bearing.

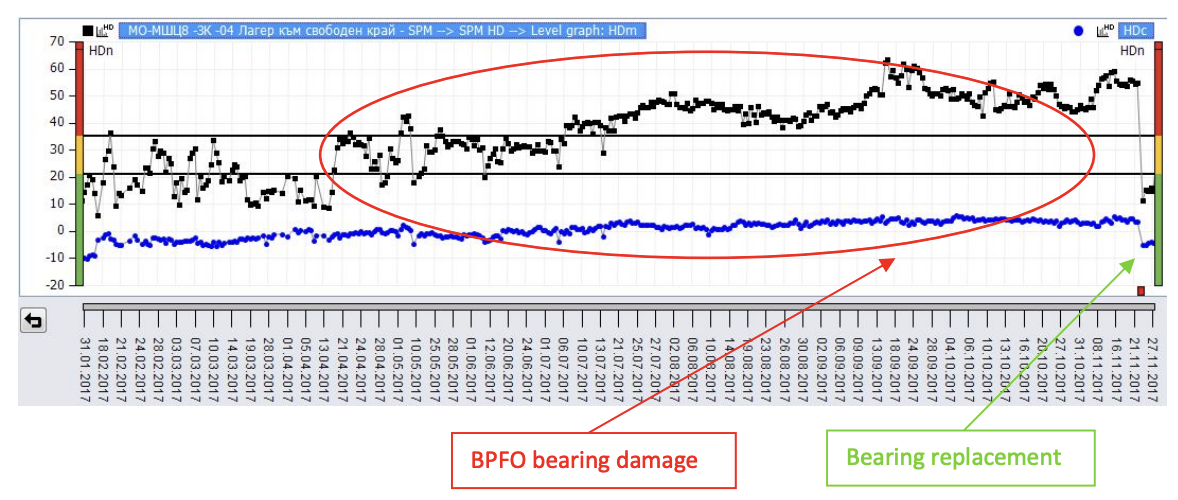

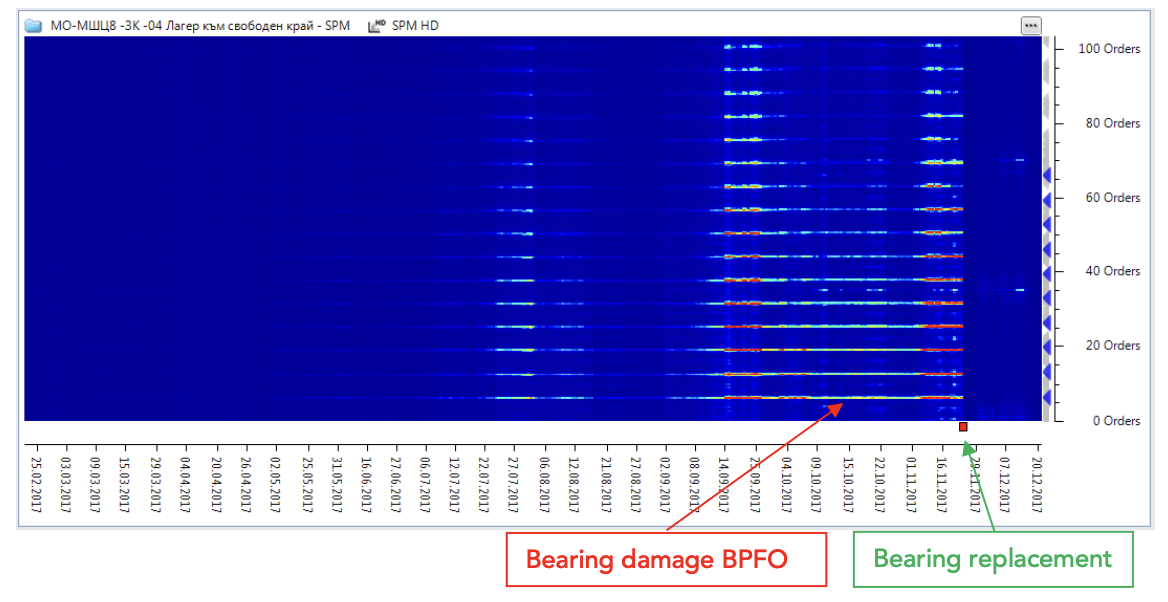

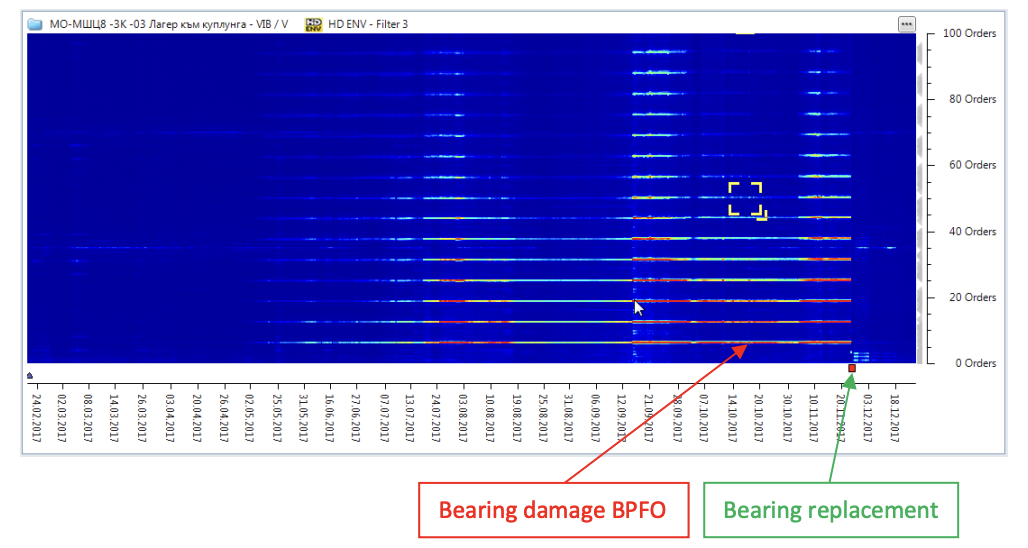

The trend graphs show results from 31.01.2017 until 28.01.2018.

At the beginning (February 2017), the SPM HD trend had varying shock pulse levels HDm/HDc (depending on the load on the mill) from 14/-2 dB (green evaluation) to 29/-3 dB (yellow evaluation). From April 23rd, 2017 the levels started to increase, and after July 2017 they exceeded red evaluation, i.e., alarm status. After September 17th, 2017 the levels reached HDm/HDc = 63/-4 dB (red evaluation). In the SPM HD Spectrum, there were clear BPFO symptom matches for the 22380YMB bearing.

On 26.11.2017, during a regular maintenance stoppage, the bearing was replaced.

Application description

The working principle of the ball mill is as follows. In a continuously operating ball mill, the feed material (copper ore) passes through the central hole of one of the caps into the drum where it is exposed to the grinding media. The grinding of the material occurs during impact with the falling grinding balls and abrasion of the particles between them. Then, the discharge of the ground material takes place through the central hole in the discharge cap or through the grid.

Image 1. Ball Mill No.8 at Asarel Medet AD, Bulgaria

Image 2. Pinion shaft with bearings

System setup

Measuring equipment

– Online system Intellinova Standard

– Shock pulse transducer, installed on pinion bearing NDE

– Vibration accelerometer, installed on pinion bearing DE

Fig 1. Typical ball mill arrangement

Measuring techniques

Pinion bearing NDE:

– SPM HD

Pinion bearing DE:

– EVAM – HD ENV Filter 3 and Filter 4

Condmaster setup

Settings in Condmaster Ruby 2018.2.3 are as follows.

SPM HD technique

– Measuring time: Same as FFT measurement

– Short / long time memory: Time signal and FFT / Full spectrum

– Upper frequency: 200 Orders

– Lines in spectrum: 1600

– Symptom enhancement factor: 5

– RPM = 150

EVAM technique

– Short / long time memory: Time signal and FFT / Peaks: 50

– Time Signal unit: ACC

– Spectrum unit: VEL

– Upper frequency: 1000 Hz

– Lower frequency: 10 Hz

– Lines in spectrum: 1600

HD ENV technique

– Filter 3 (500 – 10000 Hz) / Filter 4 (5000 – 40000 Hz)

– Short / long time memory: Time signal and FFT

– Upper frequency: 100 orders

– Lines in spectrum: 800

– Symptom enhancement factor: 3

– RPM = 150

Case description

Shock pulse measurement results from Pinion bearing, NDE

Fig 2. SPM HD trend graph HDm/HDc, from January 2017 until November 2017, measuring point Pinion bearing NDE.

Fig 3. SPM HD Time signal – Pinion bearing NDE.

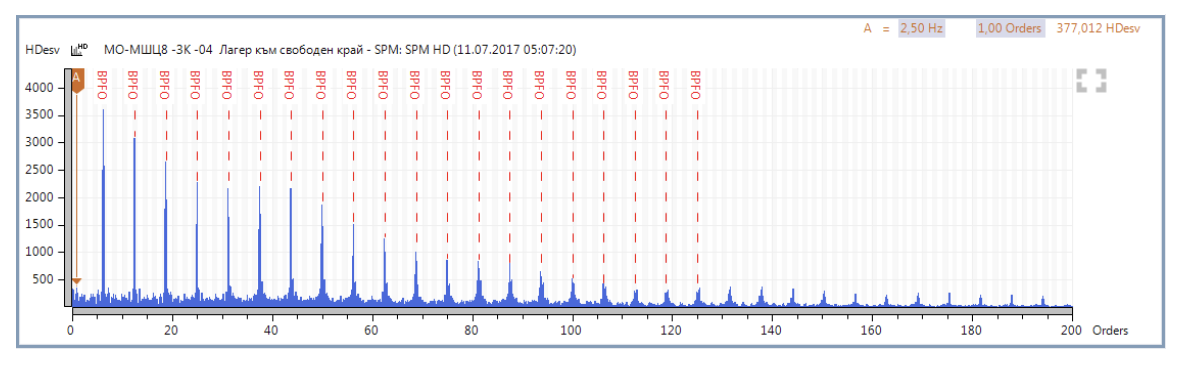

Fig 4. SPM HD Spectrum – Pinion bearing NDE – BPFO symptom match.

Fig 5. SPM HD Colored Spectrum Overview

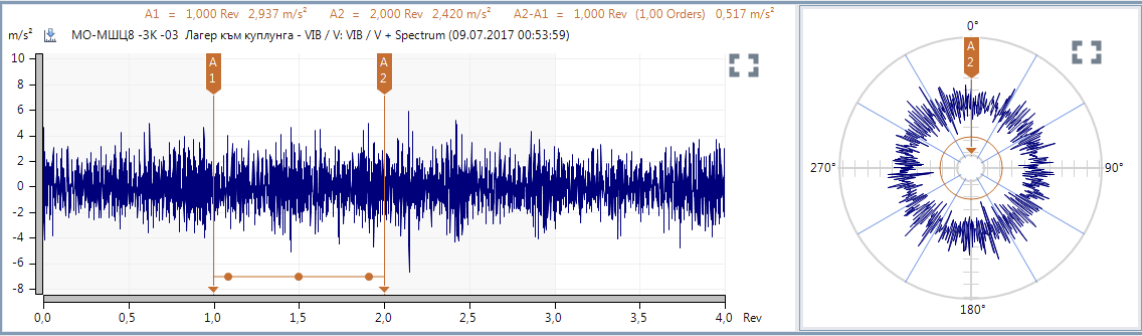

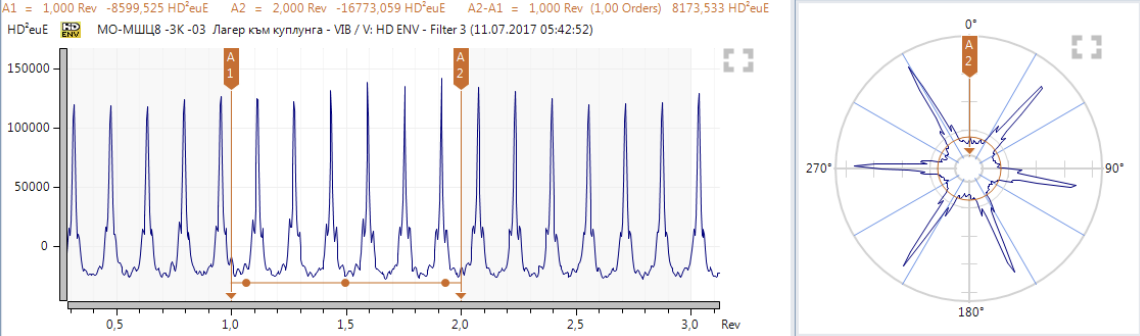

Vibration measurement results from Pinion bearing DE

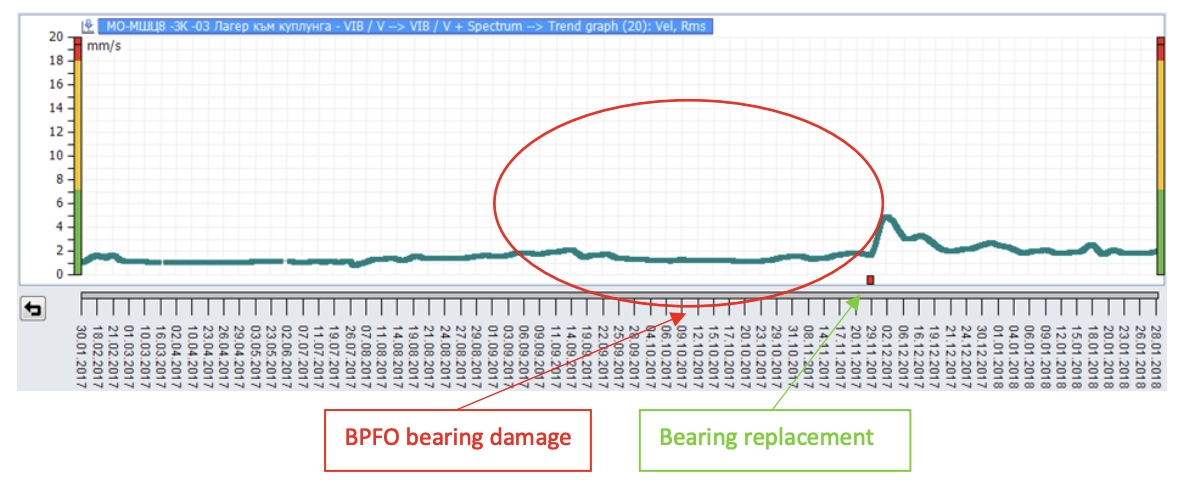

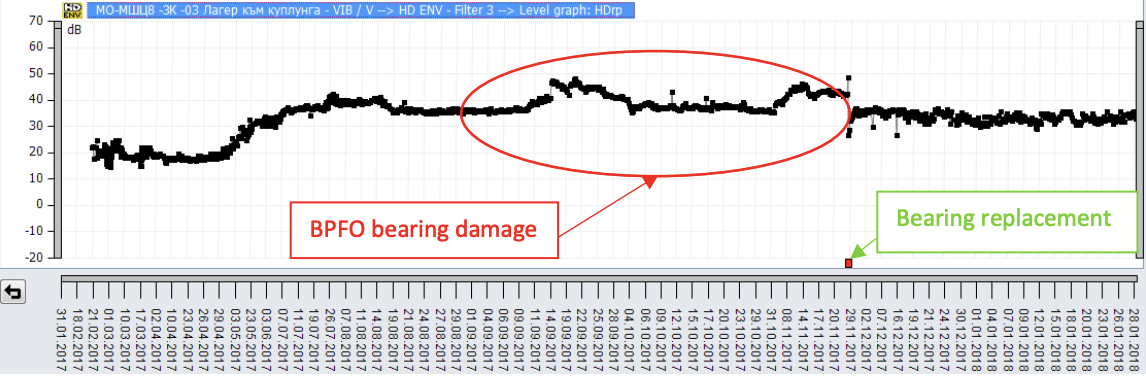

The HD ENV Filter 3 trend on the DE bearing follows a pattern similar to the SPM HD trend on the NDE bearing, and also has a spectrum showing BPFO match.

Due to the close distance between the two bearings, the vibration sensor mounted on the DE bearing picks up the signal from the NDE bearing.

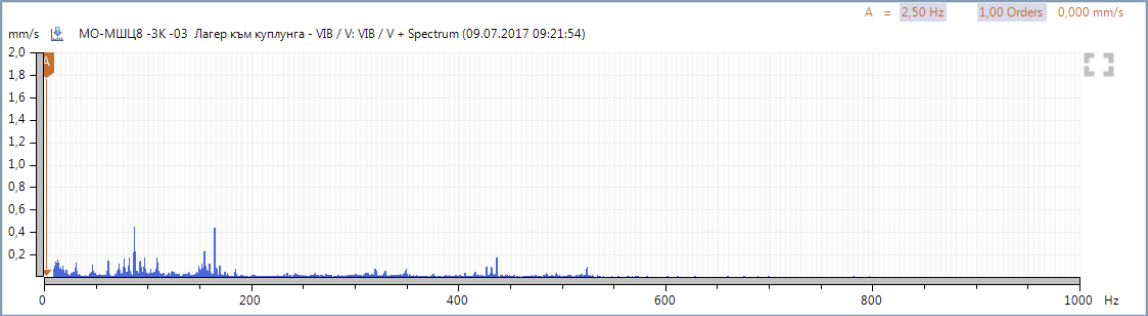

The vibration readings do not show any sign of damage.

Fig 6. Velocity trend graph, from January 2017 until January 2018, measuring point Pinion bearing DE.

Fig 7. HD ENV, Filter 3 trend graph, from January 2017 – January 2018, measuring point Pinion bearing DE

Fig 8. Velocity VEL time signal – Pinion bearing DE

Fig 9. HD ENV, Filter 3, Time signal – Pinion bearing DE.

Fig 10. Velocity VEL spectrum – Pinion bearing DE.

Fig 11. HD ENV Spectrum, Pinion bearing DE – BPFO symptom match from NDE

Fig 12. HD ENV, Filter 3, Colored Spectrum Overview – Pinion bearing DE

Appendix

The picture below show the visible signs of bearing damage on the outer race surface.

Image 3. Outer race damage.