Introduction

This pilot report describes a fan imbalance fault detected with Airius wireless vibration sensors on a waste fan in the factory of a global supplier of specialist packaging products for food and beverage. The plant has a combination of Airius wireless sensors and Intellinova Compact online system utilizing the Condmaster Ruby analysis and diagnostics software and the Condmaster.NET dashboard.

Airius wireless sensors were installed on the fan shaft bearings, measuring a number of parameters in three axes, including velocity, acceleration, enveloped acceleration (bearing condition), and temperature. Velocity measurements indicate mechanical faults such as imbalance, misalignment, and looseness. Enveloped acceleration and temperature are an indication of bearing condition and can be used to detect not only bearing distress but also lubrication deficiencies.

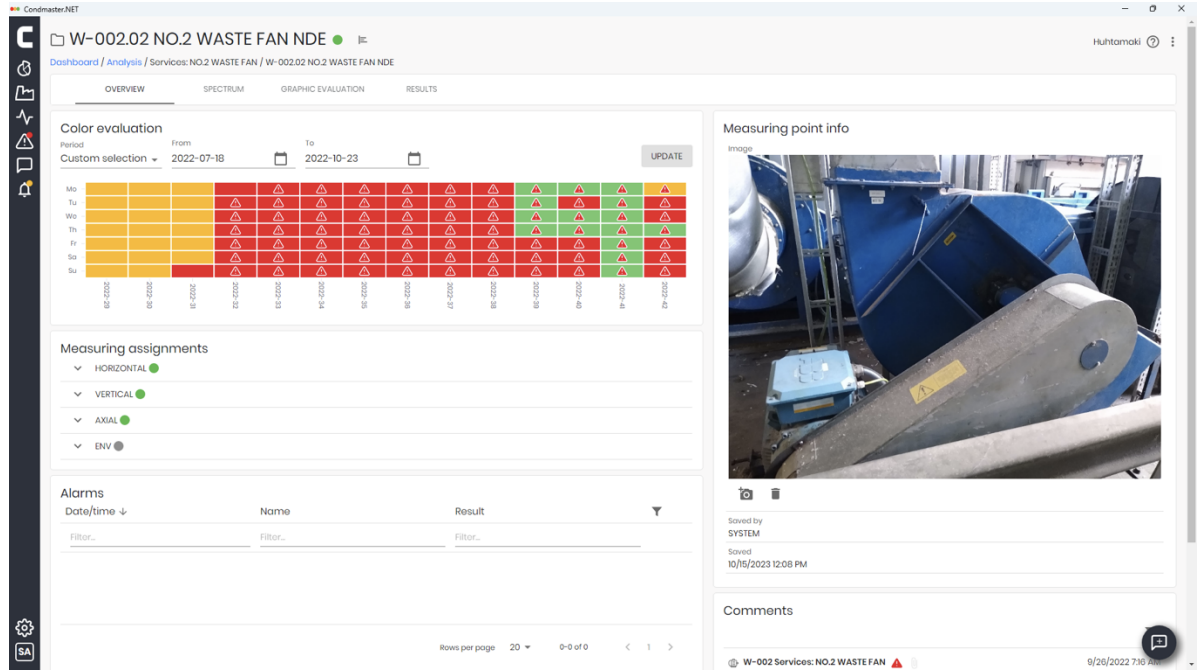

Image 1 The waste fan

Conclusion and summary

The combination of velocity, enveloped acceleration, and temperature with data collected periodically over three axes presents all the data necessary to track machine condition in a simple, easy-tounderstand green, amber, and red format. High vibration levels were recorded, and when the data was analyzed, they corresponded with 1X vibration, and it was recommended that fan inspection, repair, and remedial work be undertaken.

Image 2 Condmaster.NET dashboard.

The maintenance management team utilizes alarm emails for notification of machinery running out of range as a prompt to review either the system dashboard or supported mobile app for detailed machine information to determine corrective maintenance actions.

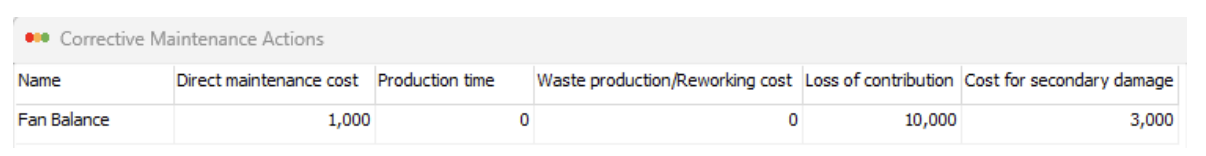

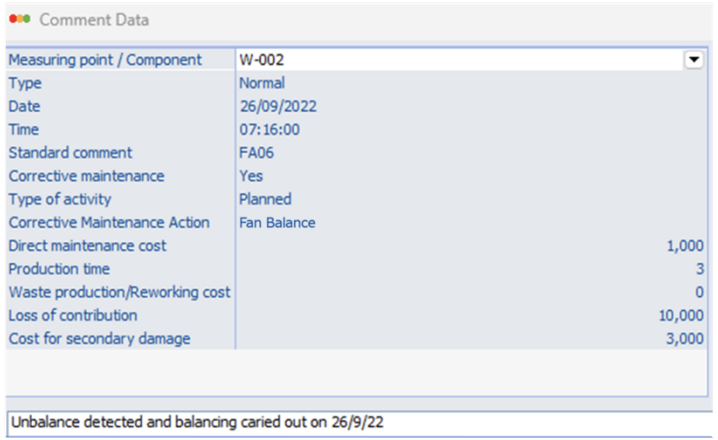

The effectiveness of the condition-based maintenance program is tracked by the maintenance management team using Plant Performer with relevant KPIs and logging corrective maintenance actions to demonstrate the cost savings made through timely intervention and scheduling of planned remedial maintenance. Condmaster Ruby provides an automatic diagnosis of machine fault symptoms when an alarm is generated. The system detected an imbalance defect which was subsequently corrected by carrying out balancing operations on the fan as described on pages 10 and 11.

System setup

The sensors transfer vibration data via WiFi over the plant WLAN to a virtual server on the company network with the Condmaster Ruby analysis and diagnostics software installed. Airius sensors were installed by gluing the mounting feet to the fan bearing housings.

Image 3 Airius sensors installed on the bearing housings.

Sensors were installed and oriented according to their reference plane:

• X-axis – horizontal plane

• Y-axis – axial plane

• Z-axis – vertical plane

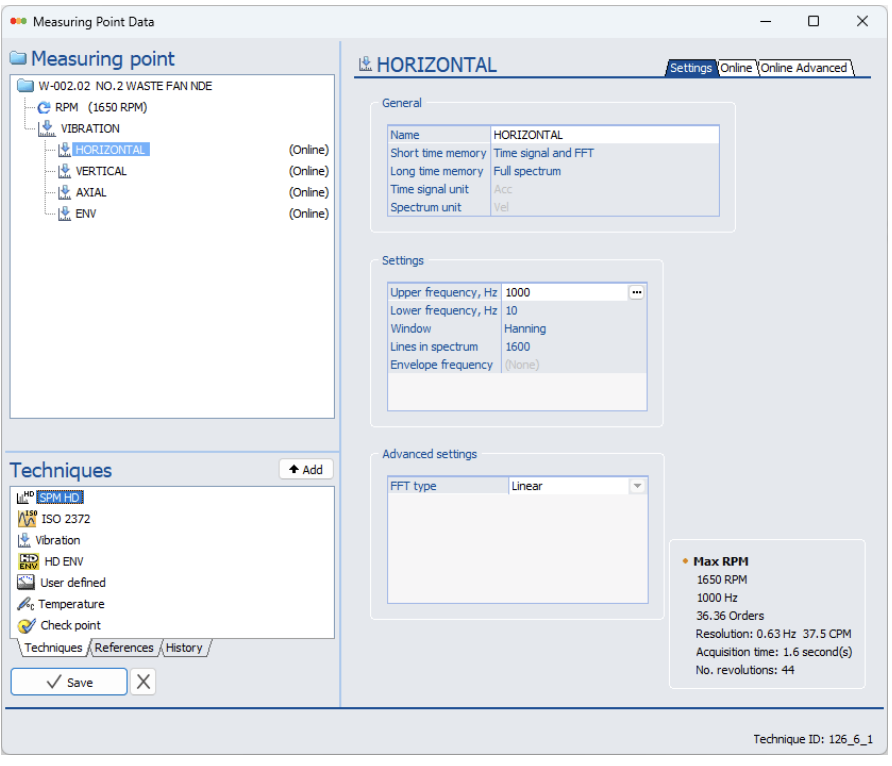

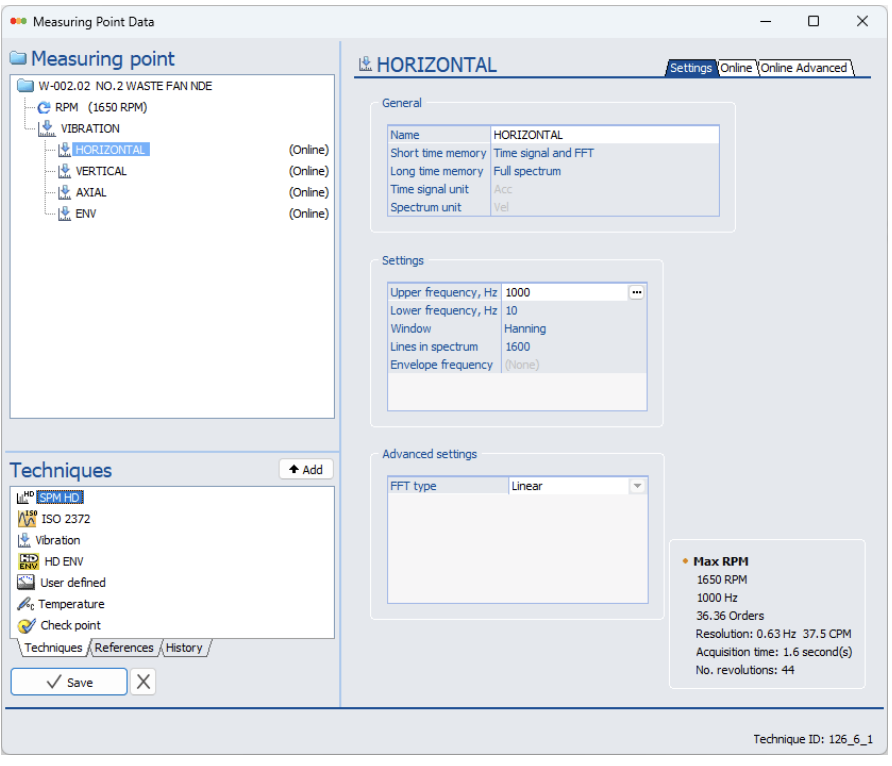

All measuring points utilize the same frequency ranges and resolution for the vibration velocity, acceleration, enveloped acceleration (bearing condition), and temperature measurements.

Image 4 Configuration of vibration velocity assignment.

Image 5 Configuration of bearing condition measurement

Image 6 Fan NDE vibration and machine symptom parameters.

Condition and alarm management, fault diagnosis

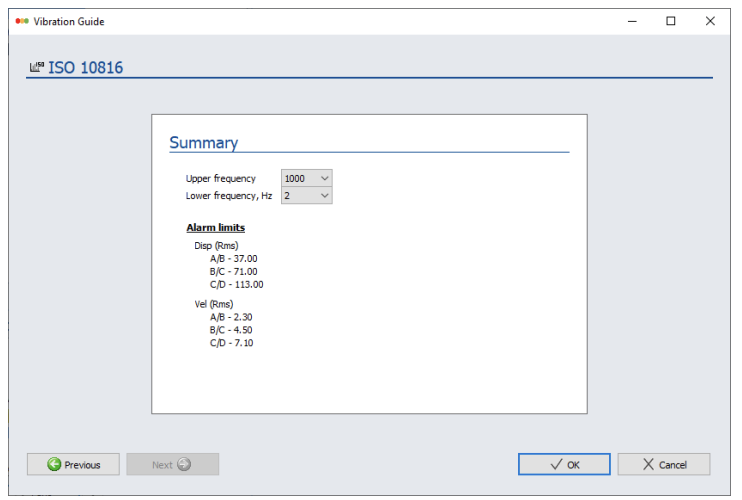

Alarm limits were established using a combination of ISO 10816 guidelines for vibration velocity – part 3, group 1, flexible support, rotational speed > 600 RPM.

Image 7 Alarm limits in Condmaster Ruby.

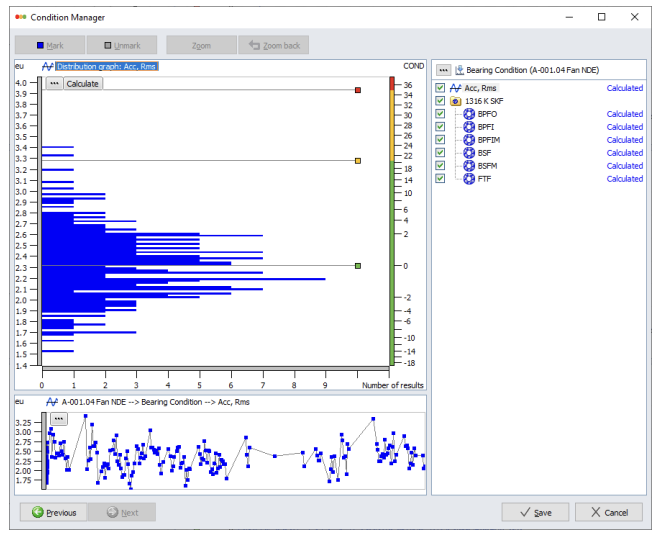

The Condition Manager in Condmaster Ruby is used for statistical alarm management for bearing condition and machine fault diagnosis symptoms.

Image 8 The Condition Manager with bearing symptoms and trend graph.

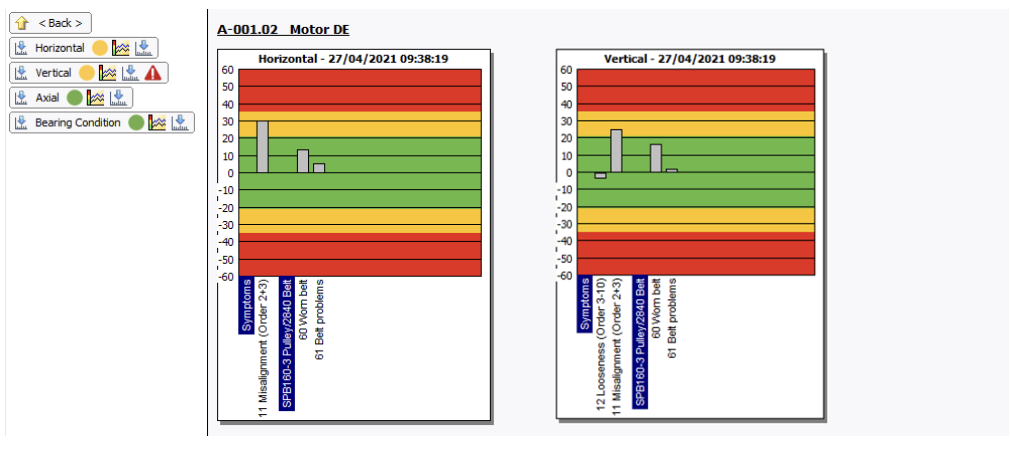

Image 9 The Misalignment symptom is on alert level in the horizontal and vertical directions.

Case description: Fan impeller imbalance (NDE)

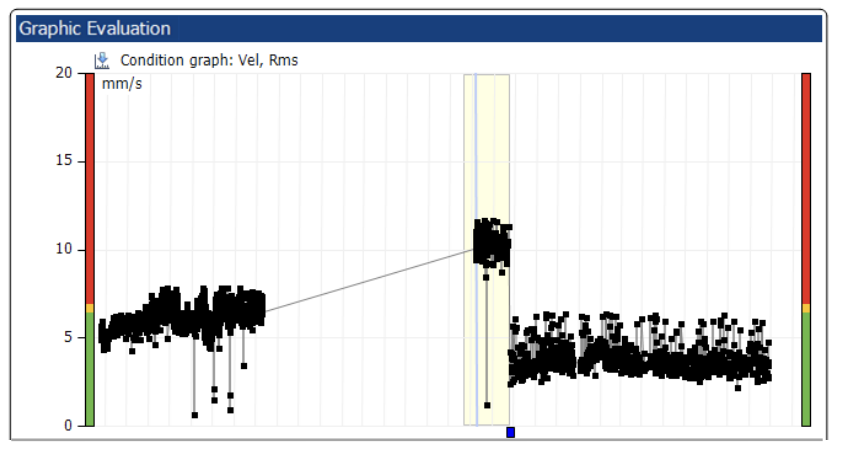

Image 10 Trend graph showing vibration levels above alarm level.

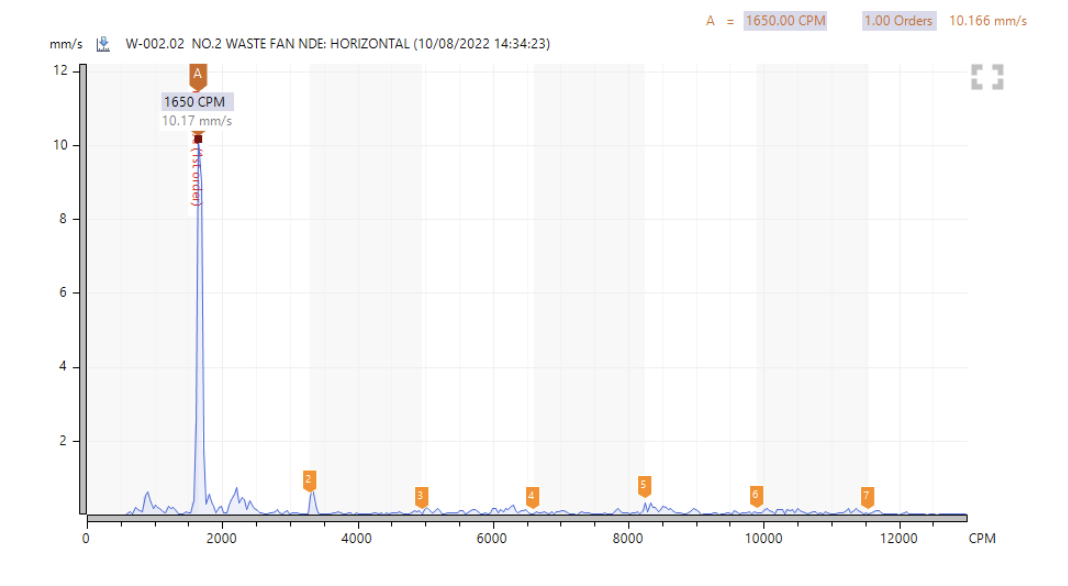

The vibration level exceeded the ISO 10816 alarm level. The imbalance symptom automatically recognized imbalance at 1X and fan shaft speed at 1650 CPM.

Image 11 Vibration spectrum showing imbalance at 1X

Image 12 The waste fan

Action taken: Isolate the guard that was rubbing on the fan shaft, likely generating spurious readings.

Image 13 Corrective maintenance comment in Condmaster Ruby

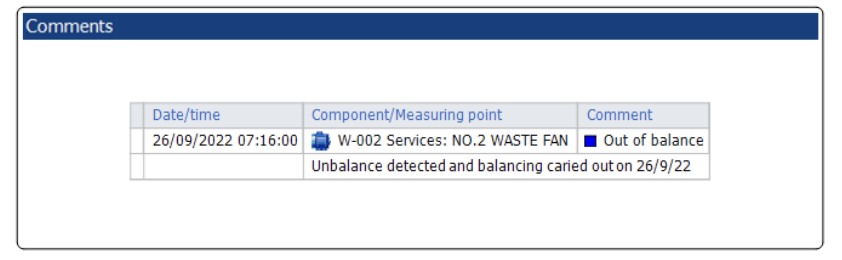

Plant Performer

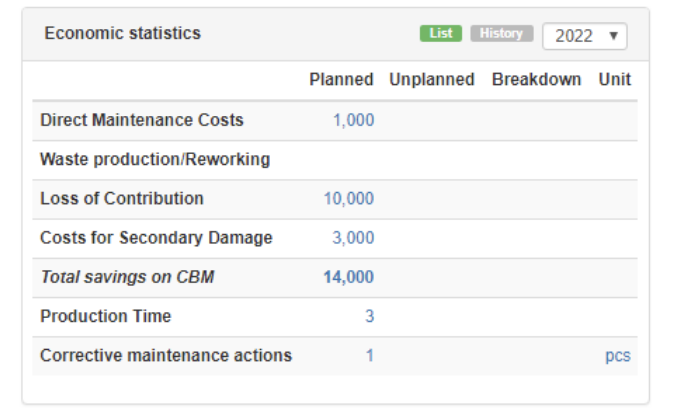

Plant Performer compiles and visualizes statistics relating to technical and economic KPIs in the OEE/TEEP area for display, evaluation, and printing.

The module is a very useful tool to demonstrate the benefits of condition monitoring and communicate its technical and economic impact to all levels of the organization. Plant Performer data can be exported to other systems by means of an application programming interface (API).

Image 14 Plant Performer visualizes KPI data

Economic justification

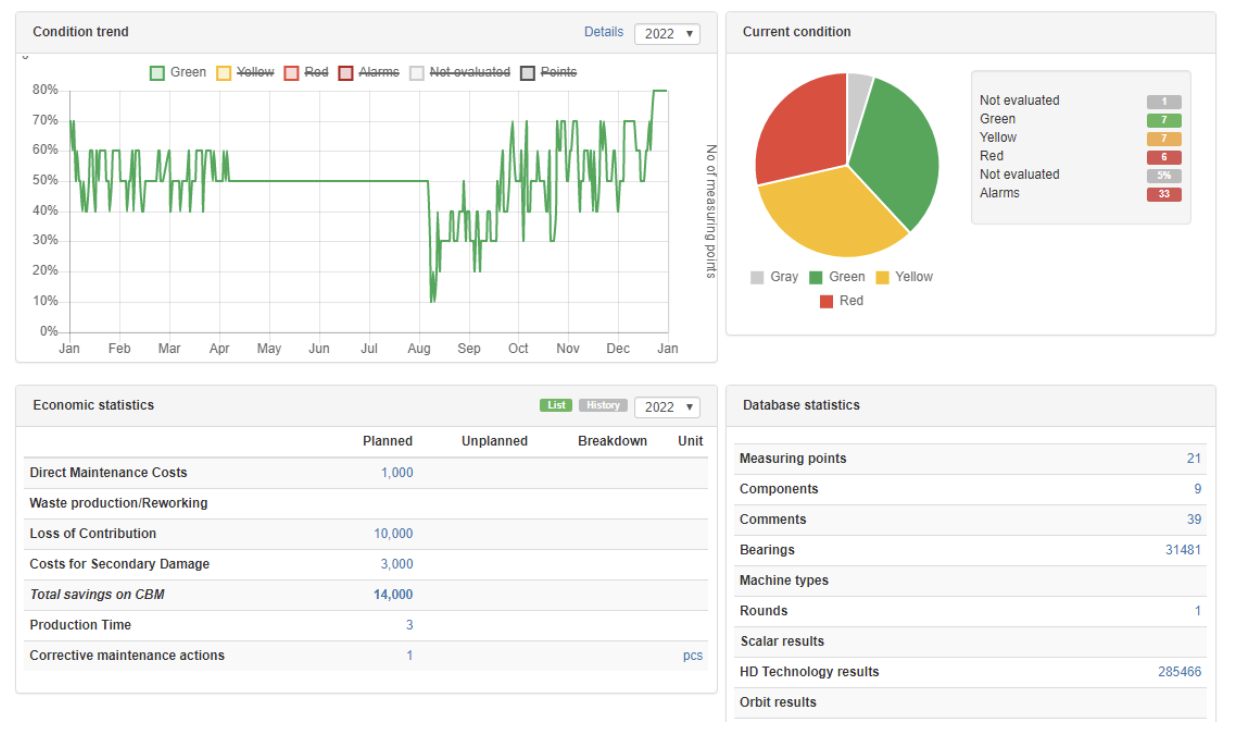

By utilizing automatic alarm handling and email notifications, timely interventions can be made to restore optimum machine condition, using proactive maintenance techniques such as balancing and precision alignment to avoid costly breakdowns.

Image 15 Input data for cost savings calculation.

Image 16 When selecting fan balancing as a corrective maintenance action on the W-02 measuring point, the costs associated with fan balancing (see Image 15) are automatically retrieved.

By building corrective maintenance action templates and using them to populate the comments register to track maintenance activity tagged ‘Unplanned’, ‘Planned’, and ‘Breakdown’, cost savings due to condition-based maintenance can be visualized.

Image 17 Plant Performer visualizes economic statistics.