Introduction

This case study describes the detection of bearing damage in a pulp washer in Norwegian pulp mill FollaCell.

MM Karton FollaCell AS, founded in 1919, has been part of Mayr-Melnhof Karton in Austria since 2013. From roundwood and sawmill chips, MM Karton Folla Cell produces approximately 140.000 tons of mechanical pulp CTMP and BCTMP per year.

MM Karton FollaCell has been an SPM customer since the 1980s. BAS-10 and A30 instruments were used before they upgraded to Leonova Diamond about three years ago. At the same time, the Intelli- nova Compact online system was installed on three refiners and three pulp washers.

Conclusion and summary

Since the installation of the Intellinova Compact online system in the spring of 2018, the mechanical condition of the bearing in question has been continuously measured. The rotational speed is relatively low, between 8 and 15 rpm.

Bearing damage under development was detected relatively soon after the startup of the system. The bearing condition was kept under continuous observation, and during the September 2019 maintenance stop, the bearing was replaced. The prewarning time was approximately eighteen months.

System setup

Measuring equipment

To monitor its three pulp washers, FollaCell uses an eighteen-channel version of the Intellinova Compact system along with shock pulse transducers type 44000.

The rpm on the pulp washer in this case study is measured and typically found to be between 8 and 15 rpm.

Measuring techniques

The SPM HD shock pulse technology is used for the bearing condition measurements.

Condmaster setup

The setup for SPM HD measuring assignments is as follows:

| Upper frequency: | 100 orders |

| Lines in spectrum: | 1600 |

| Symptom enhancement factor: | 5 |

The Symptom enhancement factor is applied to improve the signal-to-noise ratio. This factor is usually kept low for applications with little electronic noise and few mechanical shock phenomena (1 to 5). Where noise and random shocks are frequently occurring, the Symptom enhancement factor needs to be higher.

Application description

A pulp wash press is used in the chemical pulp process for dewatering, washing, and pressing the pulp. The pulp washer is critical in the pulp manufacturing process, and a malfunction may cause severe limitations or, in the worst case, a complete production stop for several days.

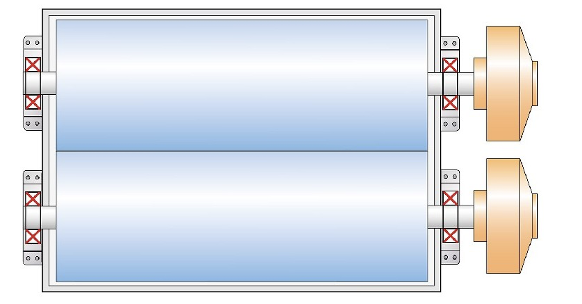

The design of the pulp washer is shown in the principal drawing below.

Figure 1 Principle drawing of the pulp washer.

Case description

- Measuring point: DWA press, North-West bearing ]

- Bearing type: SKF 24138

- Rpm: 8-15

The online monitoring system was put into operation on March 1st, 2018. Two to three months after system startup, there was an indication of developing bearing damage. The bearing condition re- mained under continuous observation, and during the planned maintenance stop in September 2019, the bearing was replaced. The prewarning time was about eighteen months.

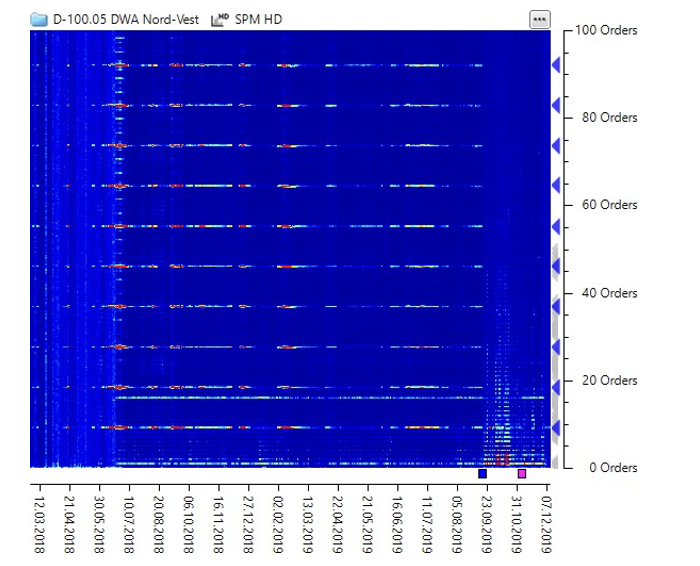

Image 1 SPM HD condition trend.

Image 2 Ball pass frequency outer race (BPFO) trend.

The Colored Spectrum Overview function in the Condmaster software can be used to reveal if a spalling process is going on in the bearing. The pattern seen in Image 3 below is typical of damage development caused by spalling, where long periods with high shock pulse levels, followed by a pe- riod of lower levels, are often observed.

Image 3 Colored Spectrum Overview.

Depending on load, RPM, temperature, and other application-related parameters, the periods of in- creasing values may last for many days or weeks, succeeded sometimes by slowly or abruptly de- creasing levels. The slowly decreasing levels are a sign that the sharp edges around a fresh spall are wearing down, while an abruptly decreasing level is a sign of metal parts breaking away from the raceways.

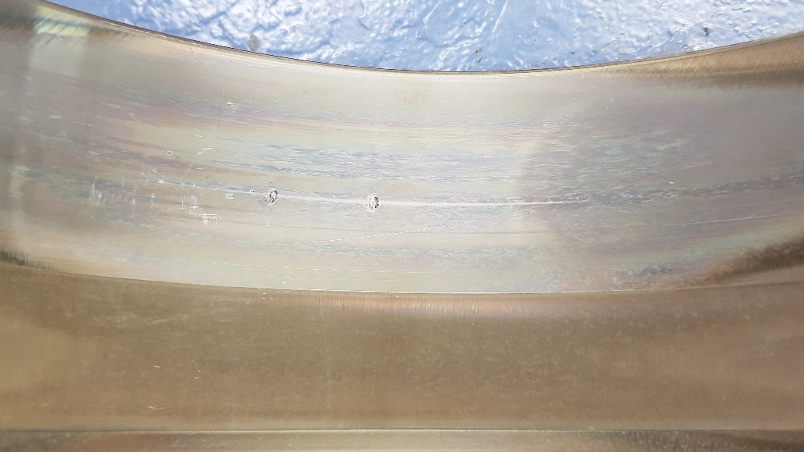

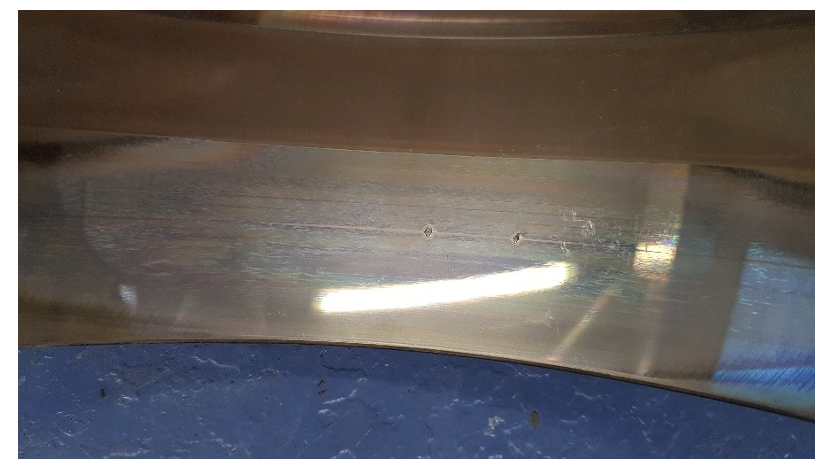

Image 1 Photograph of the outer race damage.

Image 2 Photograph of the outer race damage.