Taking full advantage of patented HD condition monitoring technology, SPM offers a complete, reliable and Ex approved solution for monitoring the condition of top drives to keep them running and minimize downtime.

The complex and costly nature of offshore drilling, coupled with intense industry competition, forces operators and contractors to optimize drilling efficiency and rig uptime – without cutting corners on safety and environment.

The top drive drilling system is mission-critical. Safe and reliable top drive operation thus has the highest priority. Any disruption to drilling due to mechanical failures will cause day rate losses and may result in consequential damage and other costly consequences, as well as endangering the safety of drill floor workers. This high-cost equipment is non-redundant and in a remote offshore environment, acquisition of spare parts is usually associated with considerable time and expense.

The SPM solution

From a condition monitoring perspective, the most complicating factors are the up-and-down motion, the varying load conditions, and extensive process induced signal interference. The low speed in drilling mode also contributes to making condition measurement challenging. Using well-proven HD monitoring technologies, we provide the technical solution required to manage these problems. In numerous successful installations, vibration and shock pulse measurement with HD technology has proven effective and reliable for gear, bearing and lubrication monitoring with excellent results.

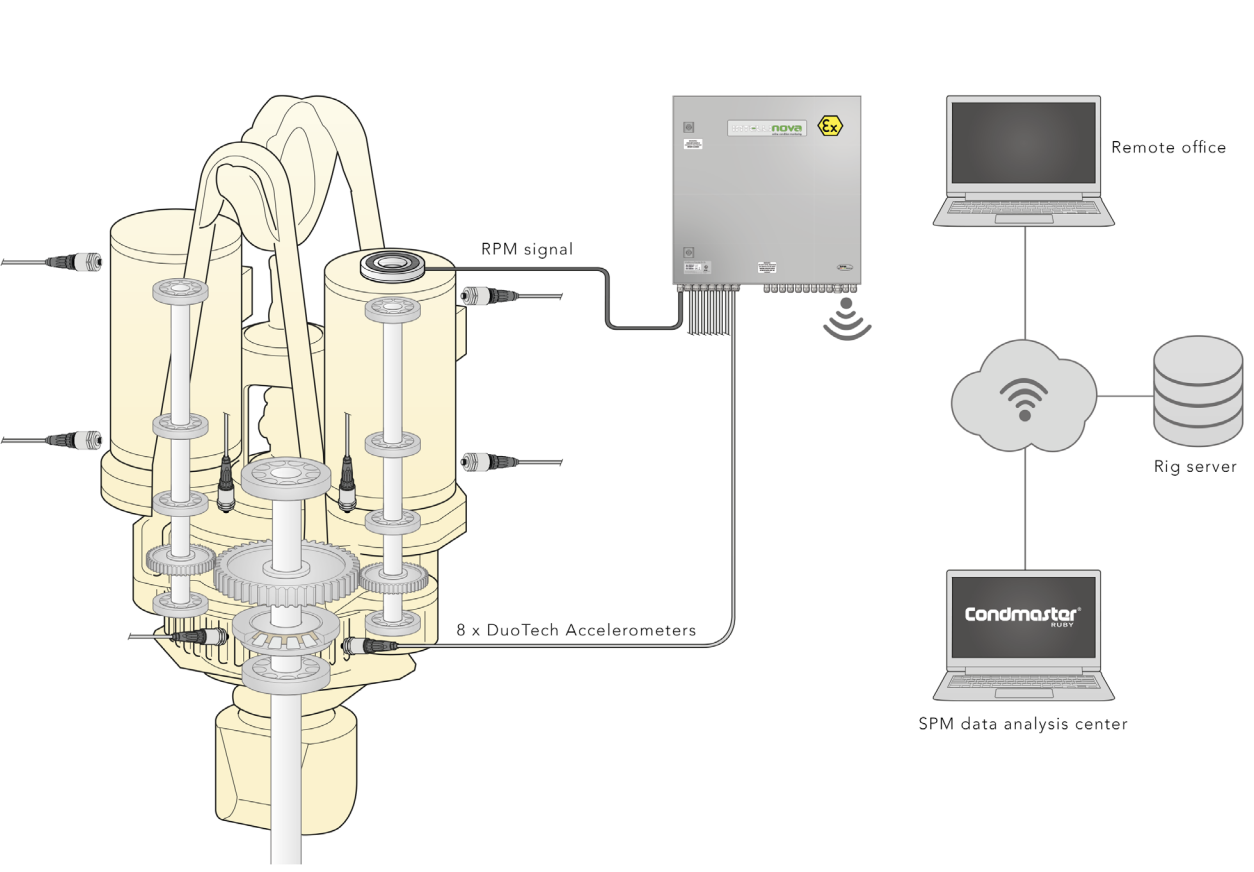

The extreme environmental conditions raise special demands on the condition monitoring solution and the installation of equipment. Rugged stainless steel enclosure, sensor installation with protection bracket and cabling with protective tube guarantee a robust installation. The Intellinova online system unit has Wi-Fi capability for network communication and data transfer to the powerful Condmaster analysis and diagnostic software. DuoTech Ex accelerometers are installed on the motor and main gearbox housings. Continuous event capturing monitors vibration levels and alerts if drilling speed needs adjusting.

Using HD technology, the system monitors bearing condition, gear dynamic behavior and gear teeth wear. It also handles fluctuating operating conditions such as RPM, load, and torque.

Cutting-edge technologies in a powerful combination

Ample forewarning and clear measurement results are key to successful top drive condition monitoring. HD technologies are the most powerful condition monitoring technologies available, providing razor-sharp condition data and exceptional forewarning times on developing mechanical faults.

SPM condition monitoring solutions transform high-definition measurement data into actionable information enabling offshore and onshore personnel to make preventive maintenance priorities for critical assets. Based on crystal-clear condition data, maintenance decisions will be well-informed and confident.

SPM Instrument is a class approved service provider, holding certifications from DNV GL, ABS, and Lloyd’s Register for condition monitoring of machinery onboard ships and mobile offshore units. We offer turnkey solutions with complete-package hardware and software, engineering, installation and commissioning, and data analysis services.

Performance, productivity, and peace of mind

Early failure detection is crucial to maximizing equipment life and performance. With fifty years of experience, SPM Instrument has the technologies, equipment, and expertise to offer efficient and flexible condition monitoring solutions for all types of industry. Through a worldwide network of resources, we provide a complete line of measurement technologies and high-performance products for industrial condition monitoring.