Maintaining the most uniform chip thickness possible is a critical success factor in optimizing the efficiency and performance of the wood-chipping process. SPM’s solution for knife wear and deviation monitoring is a process optimization tool for detecting deteriorating knife sharpness and damaged or missing knives. It enables wood processing operators to maximize raw material and pulp yields and produce high-quality pulp.

The knife system is the heart of the wood chipper. Its performance significantly impacts the final chip quality and, ultimately, the quality of the pulp.

Benefits of knife monitoring include:

• crystal-clear view of knife wear in a web-based dashboard

• production of wood chips with a more uniform size and thickness

• minimized rejects and maximized accepts

• higher raw material yields

• higher digester throughput – examples show increases in the order of 10%

• condition-based knife replacement

Double duty: One system, twice the impact

The knife wear monitoring solution is a efficient, user-friendly process optimization tool with low investment cost and rapid return on investment. It is a highly impactful complement to our highperformance machine condition monitoring solutions, designed to reduce maintenance costs and maximize equipment uptime. Using the same equipment, chipper knife monitoring can be cost-effectively combined with monitoring the mechanical and lubrication condition of the chipper’s rotating parts, such as main bearings, gearboxes, viscous couplings, and motors.

Unique, data-driven optimization of the chipping process

The knife wear monitoring solution is designed to monitor the wood chipper knives and detect overall knife wear, enabling condition-based maintenance instead of time-based replacement. A condition-based replacement strategy is superior to the typical time-based replacement for this application, as knives remaining in good condition even after their estimated lifespan will continue to produce high-quality chips, thus increasing running hours.

The solution also detects deviating and missing knives, thereby enabling the reduction of inconsistencies in chip size and thickness. This, in turn, results in more efficient production of higher-quality pulp.

Utilizing algorithms from our patented HD Technologies, the solution detects synchronous signals from the knives, providing accurate measurements even when logs are randomly fed into the wood chipper. The system takes into account gaps in the log infeed or or multiple logs being processed simultaneously. The solution offers optimization of wood chipper efficiency, ensuring minimal deviation in chip thickness, which is crucial since unevenly sized chips negatively affect the chemical impregnation process. Trends in a user-friendly, web-based knife condition dashboard visualize general knife wear over time. Performance, productivity, and peace of mind Early failure detection is crucial to maximizing equipment life and performance. With over fifty years of experience, SPM Instrument has the technologies, equipment, and expertise to offer efficient and flexible condition monitoring and process optimization solutions for all types of industry. Through a worldwide network of resources, we provide a complete line of measurement technologies and high-performance products for industrial condition monitoring.

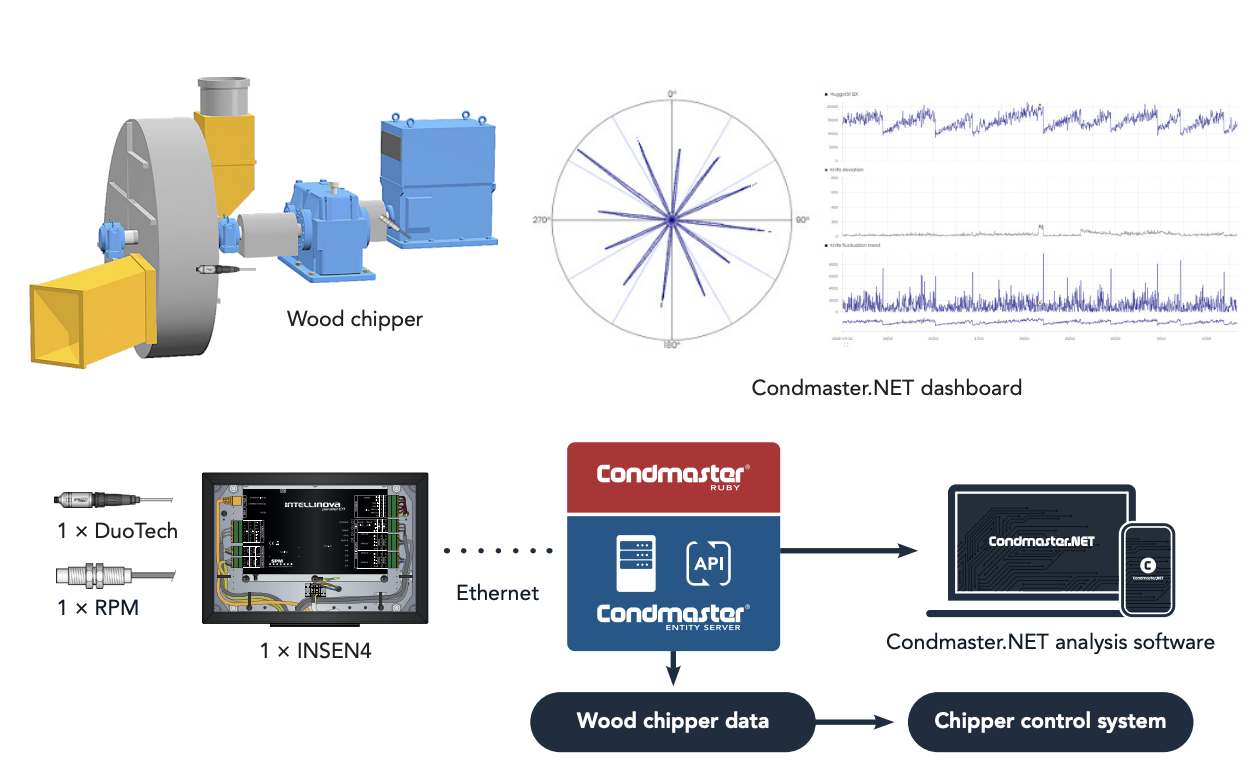

The chipper knife monitoring solution requires:

• a four-channel Intellinova Parallel EN online system

• a single DuoTech accelerometer

• one RPM sensor

• a Condmaster software license

• a subscription to the custom dashboard presenting knife wear and knife deviations

Performance, productivity, and peace of mind

Early failure detection is crucial to maximizing equipment life and performance. With over fifty years of experience, SPM Instrument has the technologies, equipment, and expertise to offer efficient and flexible condition monitoring and process optimization solutions for all types of industry. Through a worldwide network of resources, we provide a complete line of measurement technologies and high-performance products for industrial condition monitoring.