Monitoring critical elevators in the automotive industry

Low-speed elevators with short process cycles are particularly challenging targets for condition monitoring. HD technology provides reliable early warning of deteriorating mechanical condition in this critical and very common application.

The need for condition monitoring of automotive elevators is as obvious as it is challenging. Low rotational speed and short process cycles make reliable results difficult to achieve. HD condition monitoring technologies are a proven solution to maximize elevator availability.

The availability of the elevators, moving car parts between floors, is crucial, and the economic impact of a breakdown is so significant that the payback of an installed measuring unit may be as little as a few hours.

The process cycles of elevators are periodic and exceptionally short, as they move their load up or down in a discontinuous and repetitive process typically lasting ten seconds or less. The patented HD condition monitoring technologies are specifically designed to deal with these difficult measuring conditions, while also providing extremely long prewarning times. This, in turn, enables fully utilizing asset life, cutting repair costs, and minimizing the consequences of unplanned downtime.

The SPM solution

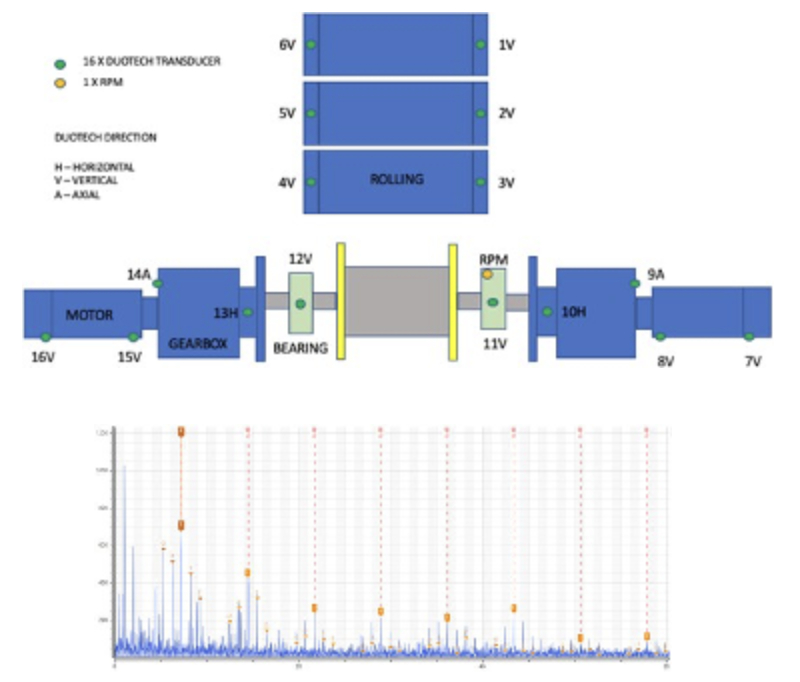

Installation is straightforward. In the upper part of the elevator, DuoTech accelerometers are installed on the rollers. At the bottom of the elevator, DuoTech accelerometers are installed on each motor and gearbox, and on each of the shaft bearings. An RPM sensor is installed on the output of the gearbox.

Sensors with sealed connectors and cable protection conduits ensure a mechanically robust instal- lation. The signals from the DuoTech accelerometer are transferred to an Intellinova online system unit nearby.

Carriage elevator set up

SPM HD spectrum perfectly matching inner race defect frequencies from carriage elevator.

Condition monitoring with Intellinova Parallel EN

The Intellinova Parallel EN system with sixteen parallel and synchronous channels provides detailed information on the mechanical condition of components using the patented HD ENV and SPM HD technologies, providing a response capacity with maximum efficiency and a minimum of production and economic losses.

Sophisticated digital algorithms make the technology less sensitive to interference from other sig- nals. Crystal clear measuring results easily understood and evaluated, make it possible to study the development of gear and bearing damages over many months.

Performance, productivity, and peace of mind

Early failure detection is crucial to maximizing equipment life and performance. With fifty years of experience, SPM Instrument has the technologies, equipment, and expertise to offer efficient and flexible condition monitoring solutions for all types of industry. Through a worldwide network of resources, we provide a complete line of measurement technologies and high-performance products for industrial condition monitoring.