- Description

- Benefits

- DSS – AI-based decision support

- Highlights

- Learn More

- Condmaster

- Features

- Modules

Description

Condmaster® – Advanced Condition Monitoring Software

Comprehensive analysis, diagnostics & troubleshooting.

Condmaster® is the core software in SPM’s condition monitoring solutions. It communicates seamlessly with all SPM Ethernet-compatible online systems as well as portable instruments, delivering a complete platform for machine condition analysis, diagnostics, and troubleshooting.

Powerful, User-Friendly & Intelligent

With a modern interface and powerful graphical tools, Condmaster® makes it simple to navigate from a plant-wide overview down to individual measuring points.

Key Capabilities:

-

📌 Flexible measuring point register for structured data management

-

📌 Full support for HD monitoring technologies

-

📌 Sophisticated analysis tools with advanced alert management

-

📌 AI-powered decision support to automate and streamline diagnostics

-

📌 Process optimization dashboards for smarter operations

-

📌 Extensive multilingual support for global usability

The intuitive green–yellow–red color coding provides instant insight into machine condition at every level.

Deployment Options

Condmaster® offers flexible deployment to fit your organization’s needs:

-

On-Premise Installation – Complete control within your IT infrastructure

-

Cloud Solution – Scalable, secure remote access with reduced maintenance

👉 Condmaster® combines expert knowledge, advanced analytics, and AI-powered decision support—transforming raw condition monitoring data into actionable insights for smarter, predictive maintenance.

Benefits

EFFICIANT CONDITION MONITORING

With a strong focus on providing powerful tools, including web and mobile apps, for users to get their job done, Condmaster Ruby gives a smooth, efficient, and productive user experience with ample customization opportunities.

DATA INTEGRATION POSSIBILITIES

Addressing the need for real-time data integration in industrial enterprise environments, the software offers options that simplify the exchange of data with automation assets, IIoT devices, and control systems in smart manufacturing.

INSTANT CONDITION EVALUATION

Simplicity and ease of use are core values in all our measurement technologies. Condition evaluation in green (normal) – yellow (caution; not yet critical) – red (warning; immediate attention) is the backbone in all our systems.

DSS – AI-based decision support

The Decision Support System (DSS) is a series of AI-based software functions particularly useful for automating and streamlining the management of large online systems. The overall purpose is to relieve maintenance personnel from having to deal with vast amounts of measurement data to analyze and find insights into root causes and complex problem-solving.

- Easier set-up of machines, measuring points, and measurement assignments

- Faster and more accurate analysis of measurement results

- Less reliance on in-house expertise

- Frees up time for maintenance staff

- Included in the platform package

Highlights

CONNECTIVITY FOR THE SMART FACTORY

Condmaster Ruby has an easy to implement, Industry 4.0-friendly REST API enabling other resources to access Condmaster data for further processing or analysis. To provide even greater opportunities for interoperability, Condmaster also supports the OPC UA standard. The capability to merge high-quality condition monitoring data into Big Data analytics and machine learning enables more accurate predictions and sharper analysis.

HIGH-EFFICIENCY DATA HANDLING

Condmaster Ruby focuses on efficiency and high through-put. Optimized database management and parallel computing enable fast execution of processes and calculations, thus supporting Big Data analytics. Timely reporting of condition data enables managers to stay up-to-date on the health of critical assets.

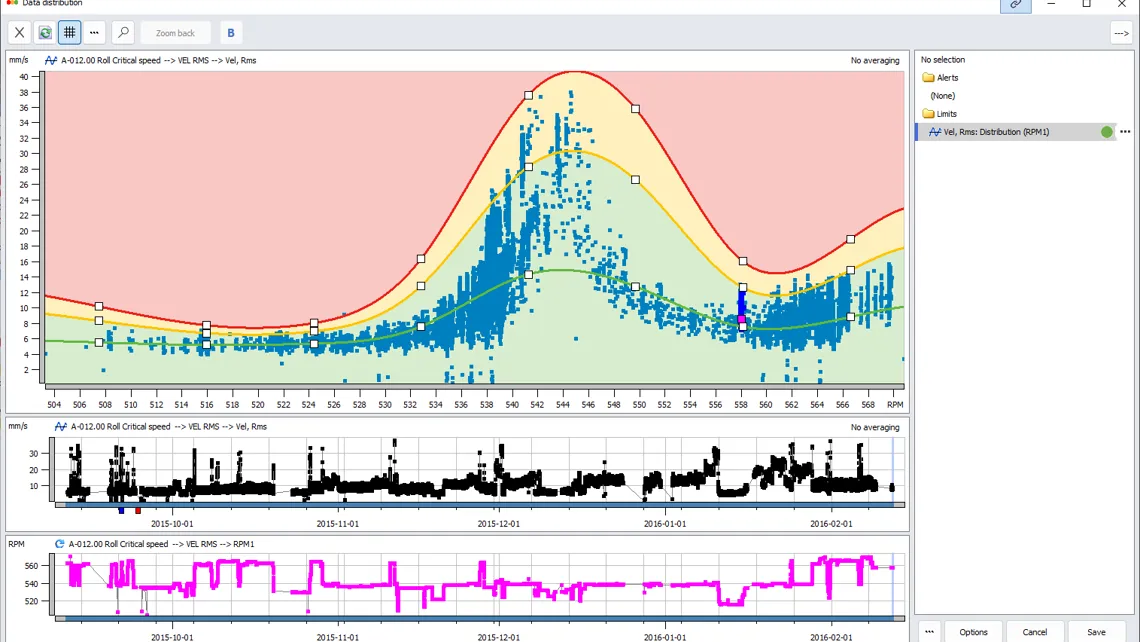

MONITOR AND OPTIMIZE INDUSTRIAL PROCESSES

Beyond traditional condition monitoring using vibration and shock pulse data, Condmaster Ruby has the capacity to handle process-related data, which can be presented in customer-specific dashboards – in Condmaster or other systems – to monitor and optimize industrial processes.

Learn More

A powerful analysis and diagnostics software

Condmaster contains the expert knowledge needed to evaluate machine condition:

• A complete bearing catalog

• Lubricant data

• Bearing life calculation

• SPM condition evaluation rules

• ISO limit values

• Mathematical models for spectrum analysis and fault symptom detection

...and much more. The software has data import and export functions, and full system security with different access levels. You can administrate all maintenance activities, set up time schedules and measuring routes, input work descriptions, and generate machine fault statistics.

Condmaster

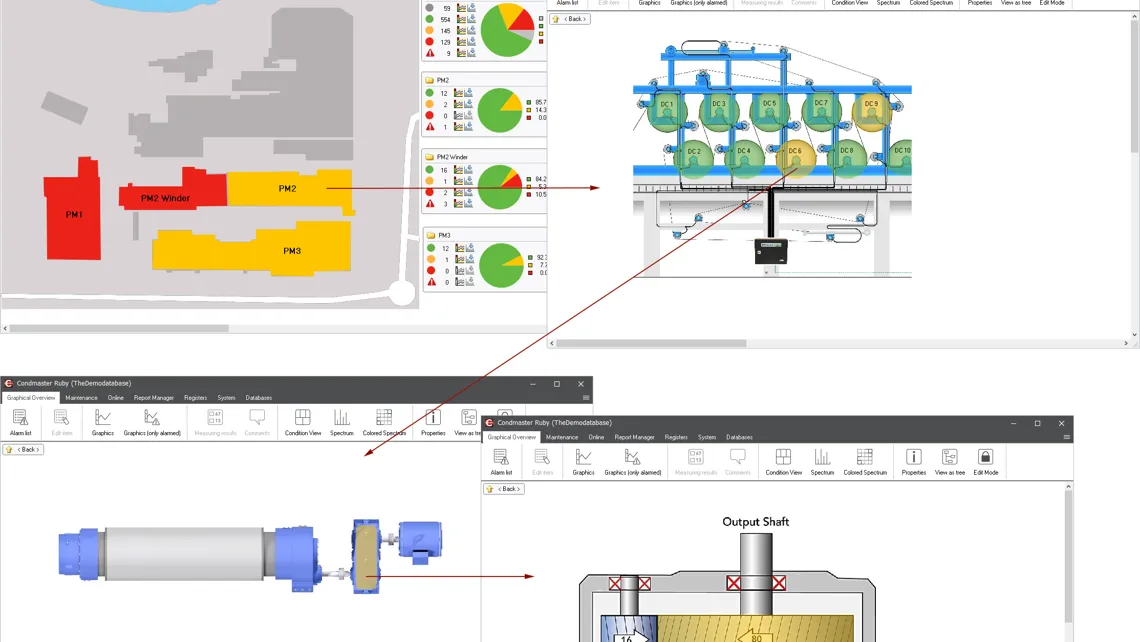

A single software for all your condition monitoring data, Condmaster Ruby lets you manage every aspect of your condition monitoring program with a single software providing everything you need to run your predictive and proactive maintenance successfully. In-depth KPI follow-up with Plant Performer

Plant Performer is very effective for demonstrating the benefits of condition monitoring and communicate its technical and economic impact to all levels of the organization. The module visualizes statistics related to technical and economic KPIs in the OEE/TEEP area for display, evaluation, and printing.

Statistics from an unlimited number of Condmaster databases can be exported and imported – such as from other divisions, production units, plants, or an entire Group – for easy comparison of data. Using an API, Plant Performer statistics can be exported also to other systems.

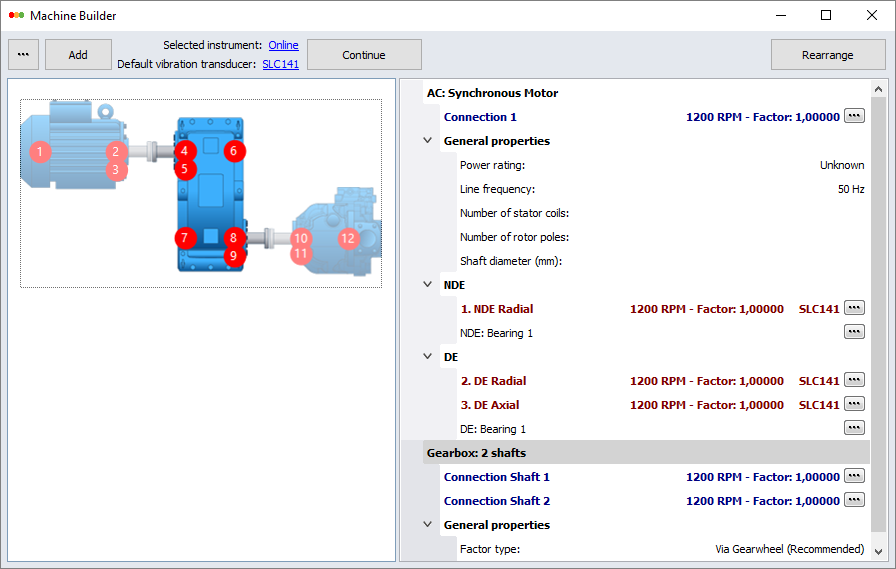

Save time with Machine Builder

The powerful and time-saving Machine Builder lets the user drag-and-drop components such as electric motors, gearboxes, fans, and pumps, from a built-in library to quickly create machines and complete applications. Condmaster automatically generates measuring points as well as the appropriate measurement assignment settings and mechanical fault symptoms to monitor.

Condmaster also creates color zones automatically, and users can save components and machines created with Machine Builder in a template library for reuse.

Features

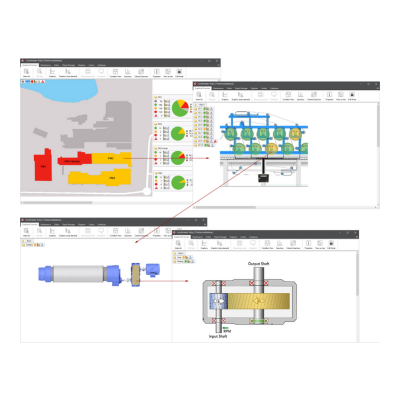

Graphical Overview

The Graphical Overview enables the visualization of plant equipment and mechanical condition in a very intuitive, top-down perspective.

Condition View

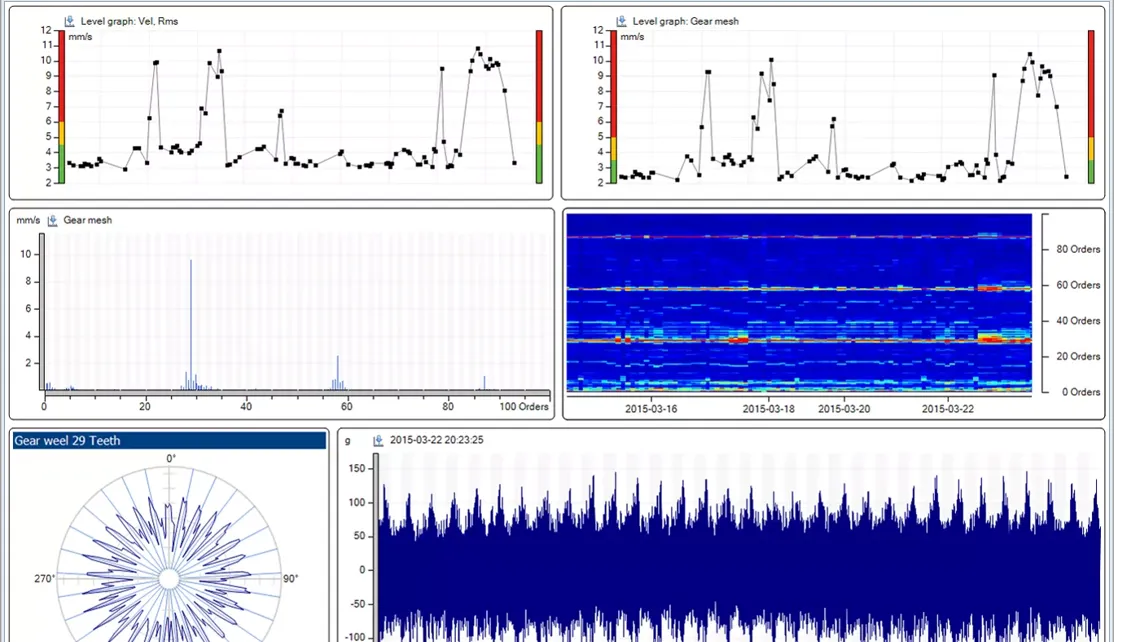

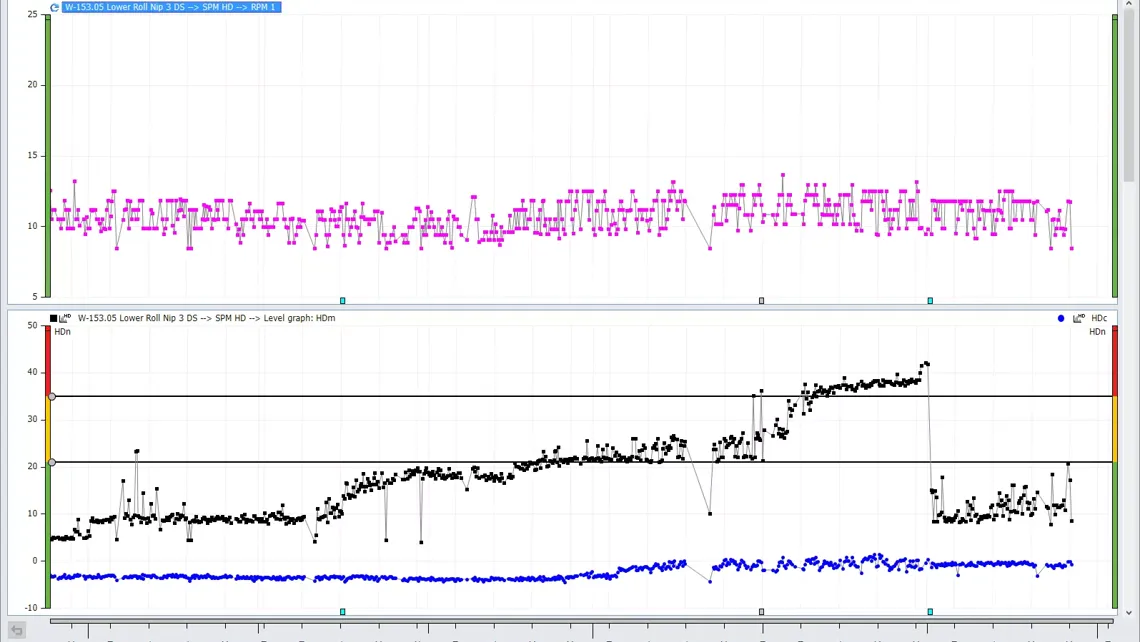

Condition View – a powerful tool for presentation and further analysis with multiple graph types and measuring assignments combined in a single window.

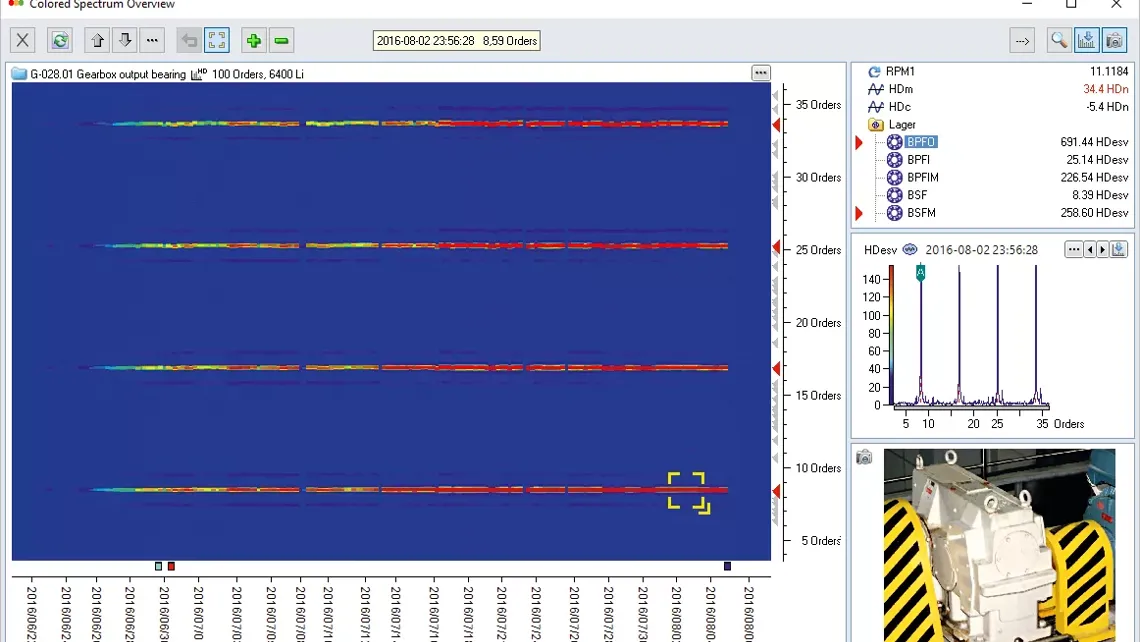

Colored Spectrum Overview

Colored Spectrum Overview presents a three-dimensional historical overview of thousands of spectrums over a longer period of time.

Graphic Evaluation

The Graphic Evaluation function offers an easy-to-understand condition evaluation in green-yellow-red scales on the Y-axis.

Spectrums and time signals

High-performance vibration analysis with razor-sharp spectrums and time signals bring root cause analysis to a new level of understanding.

Dynamic alarm management

Flexible alarm configuration where alarm limits automatically adapt to the conditions under which the machine is run at any given time.

Modules

Powerful out-of-the-box functionality

Condmaster Ruby combines extensive platform functionality and usability. The many powerful features included in the platform help support key maintenance objectives. Add-on modules can be purchased to extend functionality further as your condition monitoring program grows or business requirements change.

Measuring techniques and functions included in platform

Additional measuring techniques and functions ordered separately

Condmaster Ruby is modular, and by purchasing add-ons, its functionality can be tailored to specific organizational requirements and personal preference.

Shock pulse monitoring

- dBm/dBc

- LR/HR with Lubmaster

- SPM Spectrum™

- SPM HD Expert

Online monitoring

- Intellinova

Other

- Rule Based Evaluation

Vibration monitoring

- Vibration ISO 10816, 2372

- FFT with symptoms

- EVAM incl. Condition Manager

- HD ENV

- Multi-channel measurement

- High resolution and high frequency

- Run up/Coast down, Bump test and FRF

- Orbit analysis and Shaft Centerline Plot

- HD Order Tracking

Related Products