LineLazer Alignment Kit

$6,149.99

The LineLazer Alignment Kit, complete with sensors and free mobile app, delivers fast, precise shaft alignment with intuitive 3D guidance and easy PDF reporting.

Description

LineLazer App – Precision Shaft Alignment Made Simple

Intuitive 3D guidance for effortless alignment.

The LineLazer app transforms shaft alignment into a simple, guided process. With its intuitive 3D interface, it walks you step by step through the alignment procedure—turning a complex maintenance task into an efficient and reliable operation.

Key Features

3D Virtual Machine View – Rotate the model for a live 3D perspective from any angle, improving understanding of alignment conditions

Continuous Sweep Function – Take measurements during shaft rotation, saving valuable time and effort

Visual Misalignment Amplification – See angularity and offset clearly in both vertical and horizontal directions

Correction Guidance – Receive precise on-screen instructions for the required feet corrections

Save, Share & Document

Automatically generates detailed alignment reports

Save reports for future reference or share instantly as PDF via email

Cost-Efficient, Portable & Flexible

Works seamlessly with LineLazer sensors for precise readings

Eliminates the need for a separate data logger—just use the app on your device

Compatible with laptops, tablets, and smartphones (minimum 5” screen recommended) via Bluetooth

Includes a Demo Mode to test features and simulate alignments without sensors

👉 The LineLazer app puts fast, accurate, and user-friendly shaft alignment right at your fingertips.

Additional Information

Reliable and hassle-free machine alignment

Dual-axis high precision inclinometers measure the angle of rotation of both detector units at all times. This allows measurements in fully automatic mode, with much less than a half-turn of the shaft. The system comes with robust aluminum brackets and extendable chains for up to 480 mm (18”) diameter shafts.

The LineLazer Alignment Kit (together with Leonova Diamond) performs alignment calculations for horizontal as well as vertical or flange-mounted machines. Soft foot check, thermal growth compensation, and tolerance checks are built-in. The severity of the misalignment is indicated in green-yellow-red. The ‘Feet lock’ function automatically provides alternative alignment corrections, making the alignment procedure quick and easy.

Technical Overview

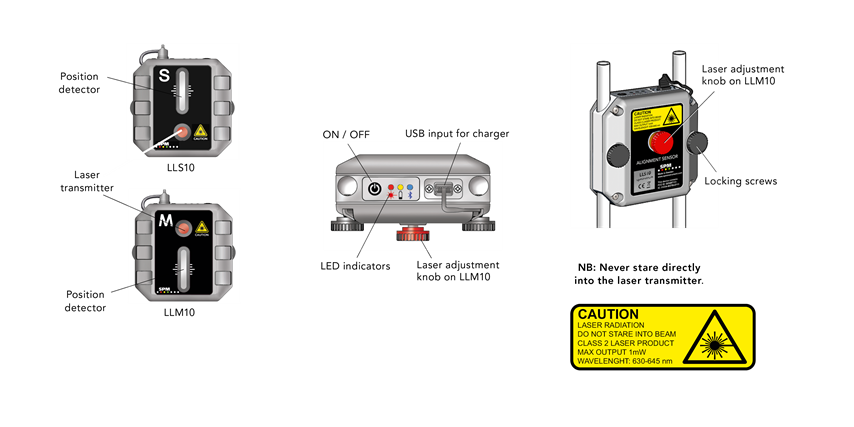

The alignment sensors are identical with the exception of the position of the laser diode and the knob for adjustment of the laser on the ‘M’ sensor. The sensors communicate wirelessly with Leonova Diamond via Bluetooth.

The alignment sensors provide maximum accuracy using a spread laser beam in combination with a 28.7 mm detector. Through digital filtering, the laser beam can be distinguished from interfering light sources. Both alignment sensors are transmitters/detectors.

The alignment sensors have dual axis high precision inclinometers that measure the angle of rotation of both alignment sensors at all times. This allows measurement in fully automatic mode, with much less than a half-turn of the shaft. Measurement results are displayed in 100ths of millimeters or 1000ths of an inch.

- Measuring range: up to 10m (32.8 ft)

- Firmware: built-in self-diagnosis and functions for calibration, signal processing

- Internal batteries: Li-ion, rechargeable

- Operating time: > 12 hours normal use

- Operating temperature: −10 to +50 °C (14 to 122 °F)

- Connector type: mini-B USB for communication and battery charge

- Communication: Bluetooth v4.0 Class II

- Housing: PC plastic/anodized aluminium

- Protection: IP65

- Dimensions: LLS10; 86x81.5x40 mm (3.4x3.2x1.6 in) LLM10; 86x81.5x46 mm (3.4x3.2x1.8 in)

- Weight: approx. 230 g

Related Products