Description

MG-4 – Reliable, Low-Cost Continuous Monitoring

The MG-4 is a stand-alone continuous monitoring unit designed to safeguard plant stoppers and other essential machines, providing peace of mind through automatic surveillance of unmanned equipment. Compact and simple to install, it requires only sensors and a few cables, making it a cost-efficient entry point into condition monitoring while remaining easy to scale up into a larger online solution.

Using the two most reliable methods for machine fault detection, MG-4 delivers shock pulse monitoring for early warnings of inadequate bearing lubrication, stressed bearings, or initial bearing damage, and vibration severity monitoring for alerts when overall vibration levels increase significantly. With programmable measuring ranges, two-step alarm levels, alarm delays, and relay combinations, the system ensures tailored and effective protection.

Condition evaluation is fully automatic, with no operating costs. Once installed, the MG-4 continuously monitors your equipment, providing reliable early warnings and helping to prevent costly downtime.

Benefits

COST-EFFICIENT

Breakdown costs are always too high. MG-4 is insurance with a payback guarantee. Choose the channel combination that gives maximum safety at lowest cost.

FLEXIBLE

MG-4 is easy to install on all types of rotating machinery. A wide range of transducers and installation accessories has proved reliable in many harsh industrial environments.

AUTOMATIC SURVEILLANCE

Safeguard your plant stoppers and other essential machines. The MG-4 is a stand-alone continuous monitoring unit, ideal for automatic surveillance of unmanned machines.

Features

The MG-4 family consists of four programmable measuring units for vibration severity (VIB) and bearing condition (SPM). The difference is in the channel combination:

MG-4 family differences |

||

| VIB channels | SPM channels | |

| MG4-1A | 1 | 0 |

| MG4-2A | 2 | 0 |

| MG4-12A | 1 | 2 |

| MG4-22A | 2 | 2 |

MG-4 provides:

- Display of measured value with continuous updates.

- Analog output 4-20 mA with programmable range in steps of 10 mm/s RMS (VIB) or 10 dB (SPM).

- Relays 250 V (1) and 125 V (2 for MG4-1, 4 for the others) with programmable alarm levels.

You can select the power supply (230 Vac, 115 Vac, or 15 to 30 Vac/Vdc), the frequency range (lower frequency range 3, 10 or 100 Hz, upper 1000 or 2000 Hz), and the SPM technique (dBm/dBc or LR/HR). MG-4 has a casing for wall mounting (IP65). Measuring time, alarm levels, alarm delay, and the channel/relay combinations are programmed, using the push buttons on the front panel.

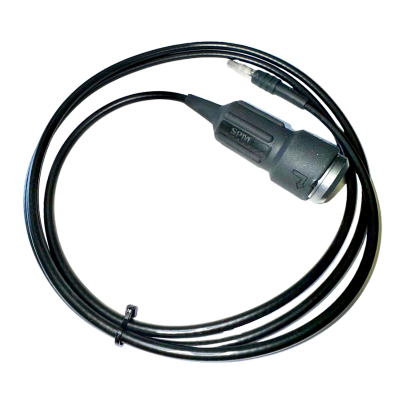

MG4-Ref11

A special kind of MG4 is the MG4-Ref11, developed for the pulp and paper industry for continuous monitoring of refiners. This unit has been adapted to the special requirements for extremely fast measurements necessary to detect imminent disc segment failure.

A shock pulse transducer is mounted on the machine housing of the refiner so that mechanical shocks from the disc segments are picked up by the transducer with the smallest possible damping. The transducer is connected to MG4-REF11 that analyses the signals received, taking into account amplitude and frequence of occurence. It also measures the RMS value of the vibration velocity according to ISO 2372. If the disc segments run together, a relay is activated and a signal is given to open the disc gap. The display shows measurement results for both channels.

MG4-Ref11 is intended for use on refiners with one rotating disc segment.

Related Products