Shock pulse transducers

Shock pulse transducers are purpose-built for bearing monitoring. With housings and bases made of acid-proof stainless steel, they are ideal for aggressive environments. Available in multiple versions with adapters and tools, they offer flexible installation for a wide range of applications.

Description

Shock Pulse Transducers – Reliable Solutions for Permanent Installations

Shock pulse transducers are purpose-built for bearing condition monitoring in permanent SPM installations. Mounted in countersunk holes on bearing housings, they detect and convert the shock pulses emitted by bearings into precise electrical signals, enabling accurate condition evaluation.

SPM offers a wide range of transducer series, sizes, and versions, each designed to meet specific application needs. With various adapters and installation tools available, shock pulse transducers can be easily fitted across different machines and environments.

Engineered for durability and accuracy, they are a trusted solution for long-term bearing monitoring and predictive maintenance in industrial settings.

Technical Overview

The shock pulse transducer 40 000, 42 000, and 44 000 series

The shock pulse transducers come in different series, each containing various sizes.

The 40 000 series

Shock pulse transducers in the 40 000 series are used in permanent SPM installations for bearing monitoring. They are installed in countersunk mounting holes on the bearing housings. A shock pulse transducer converts the shock pulses emitted by the bearing into electric signals. A coaxial cable connects the transducer with a measuring terminal or measuring device. Maximum cable length is 4 m (extendable to 100 m with external TMU).

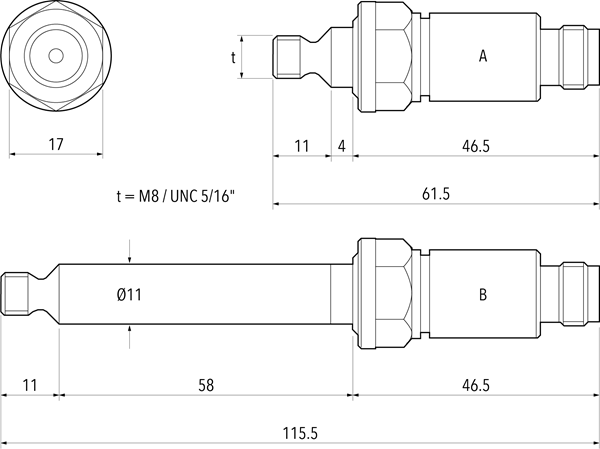

Transducer housing and base are made of stainless acid-proof steel, suitable for aggressive environments. Standard thread size is M8, with UNC 5/16" as an alternative. Standard length (A) is 61.5 mm. A long transducer (B), length 115.5 mm, is used to reach bearing housings beneath protective covers. The transducer is usually connected with a TNC plug. A TNC angle plug can be used in narrow spaces. To prevent cable corrosion in moist environments, the coaxial cable must be connected with a sealing TNC plug.

Part numbers

- 40000 Standard shock pulse transducer, M8 x1.25

- 40100 Standard shock pulse transducer, UNC 5/16-18

- 40001 Standard shock pulse transducer, M8 x1.25, extended

- 40101 Standard shock pulse transducer, UNC 5/16-18, extended

The 42 000 series (shock pulse transducers with TMU)

The shock pulse transducers with TMU (the 42 000 series) are used in permanent SPM installations for bearing monitoring, in cases where the cable length between transducer and measuring unit exceeds 4 m. The transducer with TMU (= Transducer Matching Unit) is installed in countersunk mounting holes on the bearing housings, in the same way as the 40 000 transducer. A shock pulse transducer with TMU converts the shock pulses emitted by the bearing into an electric signal and stabilizes the signal for transmission via a long cable. A coaxial cable connects the transducer with a measuring terminal or measuring device. Maximum cable length is 100 m.

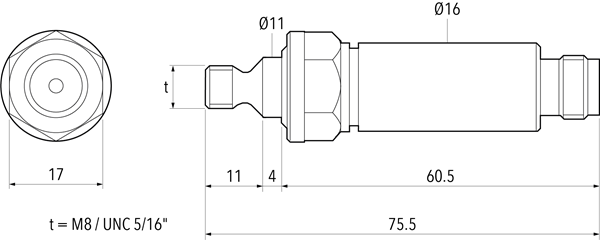

Transducer housing and base are made of stainless, acid-proof steel, suitable for aggressive environments. Thread size is M8, with UNC 5/16" as an alternative. The transducer is usually connected with a TNC plug. A TNC angle plug can be used in narrow spaces. To prevent cable corrosion in moist environments, the coaxial cable must be connected with a sealing TNC plug.

Part numbers

- 42 000 Shock pulse transducer with TMU, M8 x1.25

- 42 100 Shock pulse transducer with TMU, UNC 5/16-18

The 44 000 series

The shock pulse transducers in the 44 000 series are used in permanent SPM installations for bearing monitoring. They are installed in countersunk mounting holes on the bearing housings. A shock pulse transducer converts the shock pulses emitted by the bearing into electric signals. A coaxial cable connects the transducer with a measuring terminal or measuring device. Maximum cable length is 100 m.

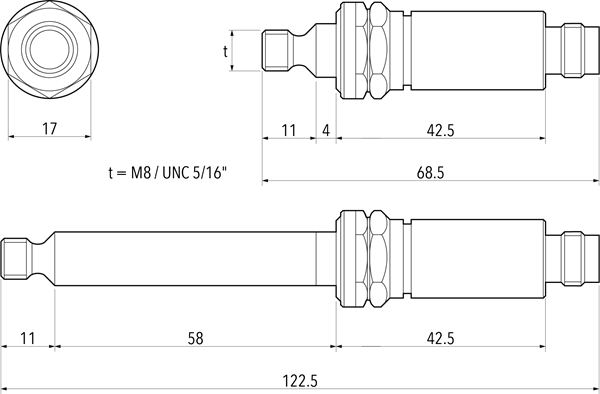

Transducer housing and base are made of stainless, acid-proof steel, suitable for aggressive environments. Standard thread size is M8, with UNC 5/16" as an alternative. The extended transducer can be used to reach bearing housings beneath protective covers. The transducer is usually connected with a TNC plug. A TNC angle plug can be used in narrow spaces. To prevent cable corrosion in moist environments, the coaxial cable must be connected with a sealing TNC plug.

Part numbers

- 44 000 Shock pulse transducer, M8 x1.25

- 44 100 Shock pulse transducer, UNC 5/16-18

- 44 001 Shock pulse transducer, M8 x1.25, extended

- 44 101 Shock pulse transducer, UNC 5/16-18, extended

Details

Which shock pulse transducer fits which SPM product?

40 000 series | 42 000 series | 44 000 series |

| Intellinova Parallel MB (INSMB4S) | ||

| Intellinova Compact | ||

| Leonova Diamond/ Leonova Emerald | Leonova Diamond/ Leonova Emerald | Leonova Diamond/ Leonova Emerald |

| Leonova Infinity | Leonova Infinity | |

| BearingChecker | BearingChecker | |

| Intellinova Standard | Intellinova Standard | |

| MG4* | MG4* | |

| CMM* | CMM* |

* Support for either 40 000 or 42 000 series depending on model.

Installation materials

Connectors, cables, and service box

We offer a wide range of connectors in composite or stainless-steel material. Composite material provides benefits such as vibration dampening and weight reduction, while stainless steel can withstand mechanical forces and works both in high and low temperatures, etc.

For our connectors, we supply different types of cables, and to further secure the installation, we supply uncovered, acid-proof stainless steel conduits. These are protective covers slipped onto the cable and fixed to the transducer at the connector. Stainless steel cable clips are available for holding the conduit. For the protection of cable joints from moist and water, a stainless, acid-proof steel service box is available.

Related Products