Description

Vibration Transmitters – Simple, Accurate, and Easy to Integrate

These vibration transmitters provide a 4–20 mA output signal proportional to vibration velocity, enabling continuous monitoring of machinery health. The signal can be transmitted directly to standard process control systems such as PLC, DCS, and SCADA, making them a practical and widely compatible solution.

Operating from any standard 4–20 mA loop, the transmitters require no additional power supply, simplifying installation and minimizing costs. Each unit features a unique microcontroller design and stored calibration data, ensuring accuracy, reliability, and long-term stability in operation.

For ease of use, all transmitters are equipped with a top connector, allowing fast and straightforward installation in a variety of industrial environments.

With their robust design and easy integration into control systems, these vibration transmitters provide a dependable and cost-effective solution for machine condition monitoring and predictive maintenance.

Technical Overview

Our vibration transmitters come in a variety of sizes, configurations, and specifications to match your needs. All transmitters are internally isolated and have an operating temperature range of −40 to +85 °C (−40 to +185 °F). The frequency range is specified for the transmitter when permanently installed. The measuring results will be affected at higher frequencies when using a magnetic foot.

Connection alternatives:

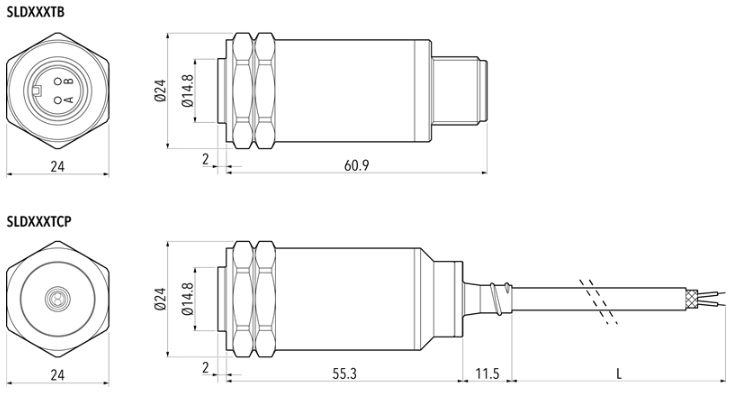

TB = 2-pin connector MIL-C-5015

TCP = Integral cable (3, 5, 10, or 20 m) with an adapter for protection tube

4-20 mA vibration transmitters with top entry/cable

Part number | Ex | Mounting thread | Connection | Frequency range | Sensitivity |

| SLD722 | - | M8 tapped hole for mounting stud* | TB, TCP | 2-1000 Hz | 0-12.5 mm/s |

| SLD723 | - | M8 tapped hole for mounting stud* | TB, TCP | 2-1000 Hz | 0-25 mm/s |

| SLD724 | - | M8 tapped hole for mounting stud* | TB, TCP | 2-1000 Hz | 0-50 mm/s |

| SLD732 | - | M8 tapped hole for mounting stud* | TB, TCP | 10-1000 Hz | 0-12.5 mm/s |

| SLD733 | - | M8 tapped hole for mounting stud* | TB, TCP | 10-1000 Hz | 0-25 mm/s |

| SLD734 | - | M8 tapped hole for mounting stud* | TB, TCP | 10-1000 Hz | 0-50 mm/s |

| SLD822 | Ex | M8 tapped hole for mounting stud* | TB, TCP | 2-1000 Hz | 0-12.5 mm/s |

| SLD823 | Ex | M8 tapped hole for mounting stud* | TB, TCP | 2-1000 Hz | 0-25 mm/s |

| SLD824 | Ex | M8 tapped hole for mounting stud* | TB, TCP | 2-1000 Hz | 0-50 mm/s |

| SLD 832 | Ex | M8 tapped hole for mounting stud* | TB, TCP | 10-1000 Hz | 0-12.5 mm/s |

| SLD833 | Ex | M8 tapped hole for mounting stud* | TB, TCP | 10-1000 Hz | 0-25 mm/s |

| SLD834 | Ex | M8 tapped hole for mounting stud* | TB, TCP | 10-1000 Hz | 0-50 mm/s |

* The mounting studs are available with thread sizes M6, M8, M10, and UNF 1/4″.

Installation Materials

Connectors, cables, and service box

We offer a wide range of connectors in composite or stainless-steel material. Composite material provides benefits such as vibration dampening and weight reduction, while stainless steel can withstand mechanical forces and works both in high and low temperatures, etc.

There are different types of cables for our connectors, and to further secure the installation, we supply uncovered, acid-proof stainless steel conduits. These are protective covers slipped onto the cable and fixed to the transducer at the connector. Stainless steel cable clips are available for holding the conduit. For the protection of cable joints from moisture and water, a stainless, acid-proof steel service box is available.

Related Products