Introduction

This case study describes the journey of condition monitoring on Archimedes screw pumps in the water industry.

British public utility company Severn Trent has successfully used Leonova Emerald/Diamond portable instruments from SPM to monitor slow-speed rotating biological contactor (RBC) bearings. They wanted to expand their portfolio of monitored assets to include rotary screw pumps using Intellinova online systems. These assets have been causing problems for a very long time with poor maintenance practices.

SPM HD has been used to monitor the very slow-rotating RBC bearings (about 1rpm). Other HD technologies were used throughout this proof-of-concept, and it is clear to see the early warning signs these HD technologies can detect compared to other techniques.

Conclusion and summary

This case shows the advantage of using HD technologies in picking up early warning signs of bearing wear, giving engineers time to plan maintenance activities on equipment whose function is critical for the environment and where potential failure is associated with high costs.

Application description

The Archimedes screw has been used since Egyptian times as a method to raise water from deep wells. They are used today commonly in the water industry, using a motor and gearbox to move wastewater from a lower to a higher level.

The benefits of these screw pumps are that they are self-regulating, non-choke, and are used in low lift, high flows.

Figure 1 Screw pump working principle diagram.

Image 1 The motor and gearbox

Background

Thanks to the success in monitoring the RBCs, Severn Trent wanted to expand their condition monitoring portfolio to monitor screw pumps. Due to the high cost of failure and work-around costs, the pumps were a troublesome asset. An added problem is the difficulties in getting spare parts for the pumps, as lead times are considerable. There is also the added cost of environmental pollution, as the drains get blocked up in large residential areas when a failure occurs.

Economic justification

The economic impact of a failure is an extra £10K/week in overpumping costs. Pollution prevention fines are also huge.

When a failure occurs without catastrophic damage, the cost is usually £100-£150K, which includes screeding. This would be the top and bottom bearings with possibly the gearbox.

The cost of changing a bearing only – which condition monitoring would enable them to do – is £2.5K labour, £1.5K contract, lift £2K = £6K (no contract workers). These failures regularly occur in the water industry, and at the time of writing, there are no alternatives other than using cheap contractor systems that offer no real value.

Health and safety aspects

The two main issues from a health and safety perspective are that the flow of water must be regulated while inspecting/changing the bottom bearings to ensure the work chamber is not flooding.

The atmosphere needs to be checked in the area due to potential hazards coming into the works area.

Environmental effects

If a screw pump fails, pollution and flooding are the main environmental effects, and huge fines are in place for any excess.

System setup

Measuring equipment

Severn Trent uses a mix of handheld Leonova Diamond instruments and online Intellinova Compact units for condition monitoring. For the first case below, only a shock pulse adapter was installed, and shock pulse readings were taken. In Case 2, a fixed Intellinova system was used.

Measurement technologies

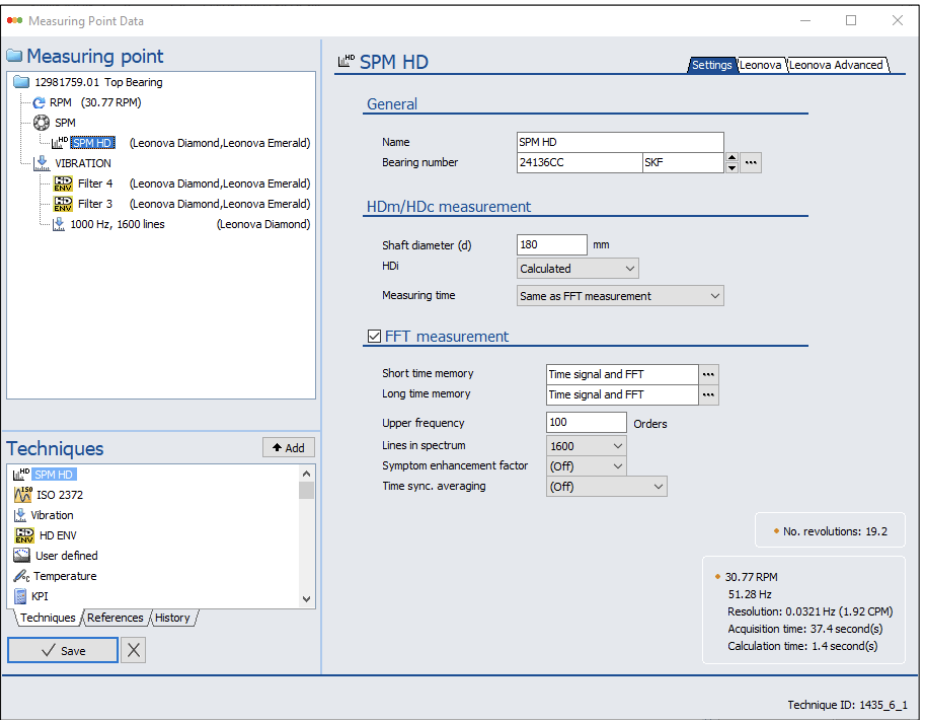

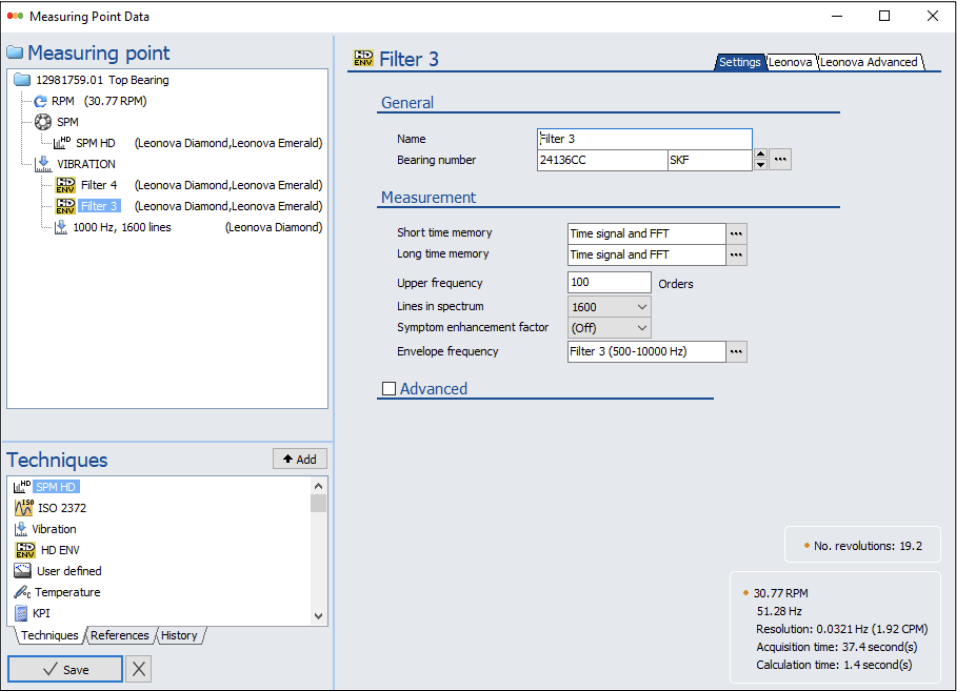

Standard vibration and acceleration measurement were used on the high-speed motor and gearbox input. HD technologies were used from the output of the gearbox, with a fixed speed at 30.77 rpm measured with a tachometer.

Condmaster setup

SPM HD and HD ENV are used on the top bearing with the Leonova Diamond on a 24136CC bearing. As it is a fixed speed bearing, no triggers were set, and the number of lines was set to 1600, giving an acquisition time of 37.4 seconds.

Image 2 SPM HD measuring assignment configuration in Condmaster.

Image 3 HD ENV, Filter 3 measuring assignment configuration.

Case descriptions

Top bearing

The below measurements were taken on a top bearing using a Leonova Diamond. The screw pump had previously failed on the gearbox, and Severn Trent was told that the top bearing was not affected. Severn Trent used their instrumentation to inspect the top bearing and found some raised shock pulse levels.

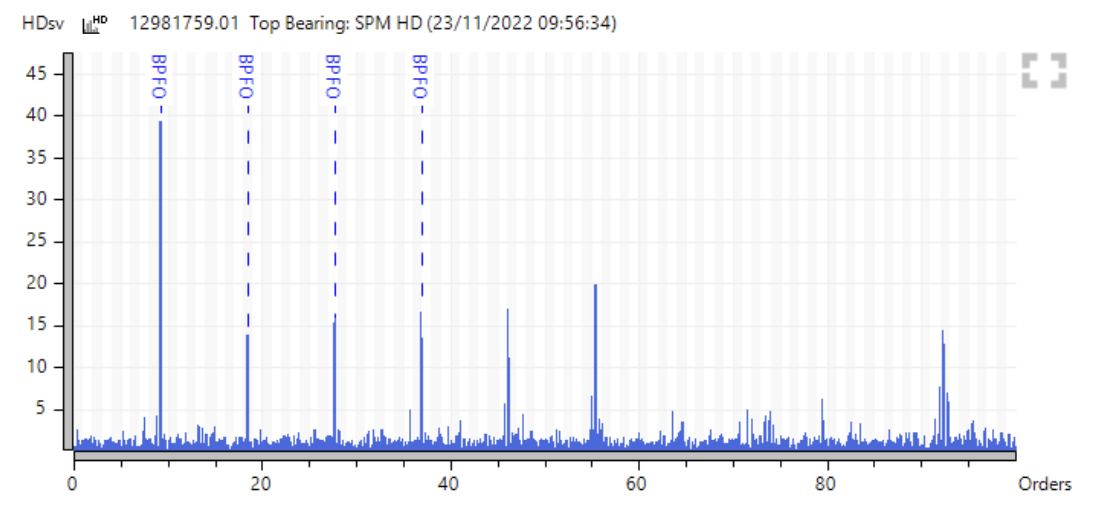

The below trend shows exact matches for the BPFO symptom, which were raised considerably.

Image 4 SPM HD condition trend. The gap between readings is because measurements are taken roughly once a month.

Image 5 SPM HD spectrum from the top bearing, with very clear BPFO matches.

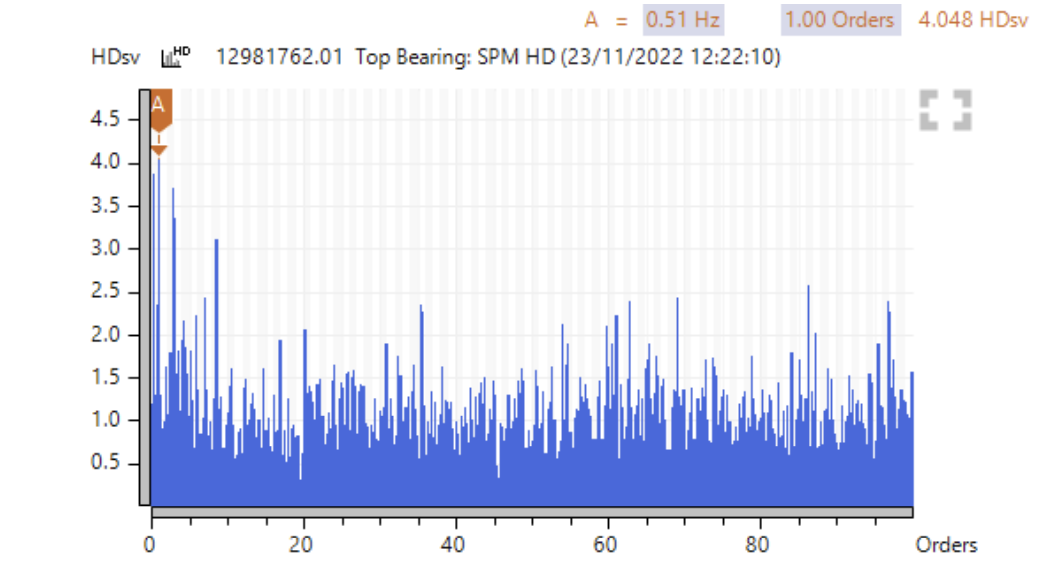

The graph below shows the readings after the bearing replacement.

Image 6 SPM HD spectrum after bearing replacement.

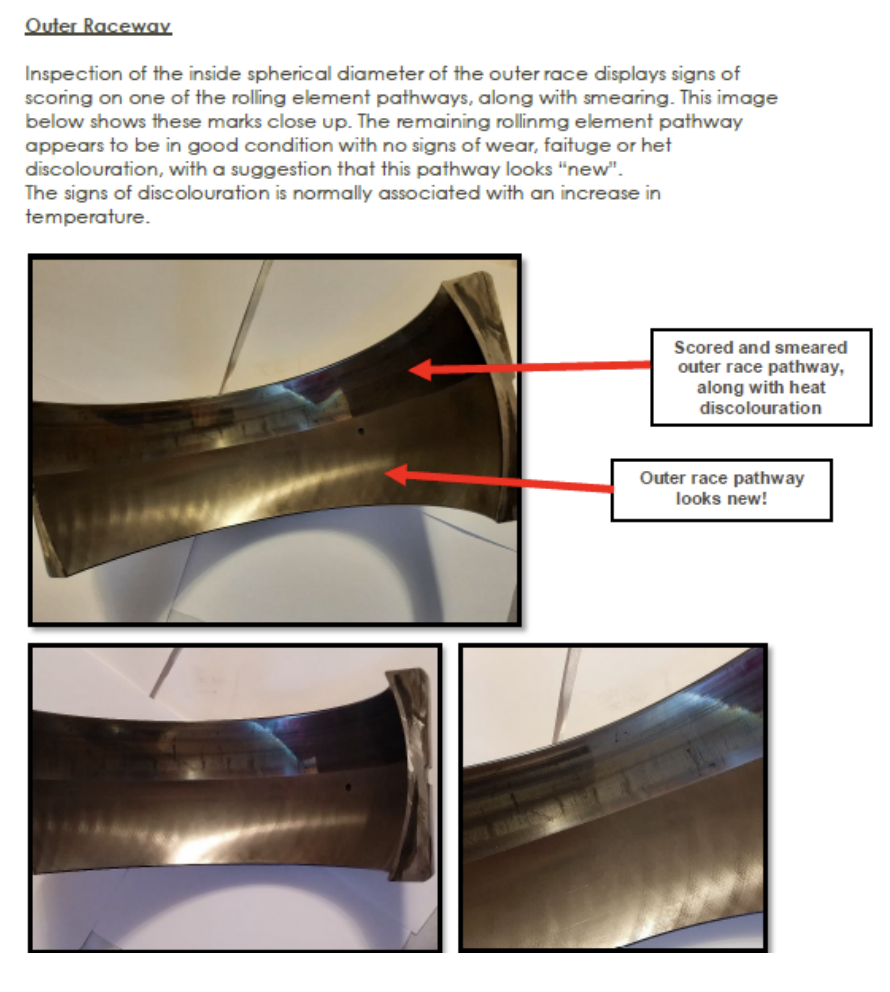

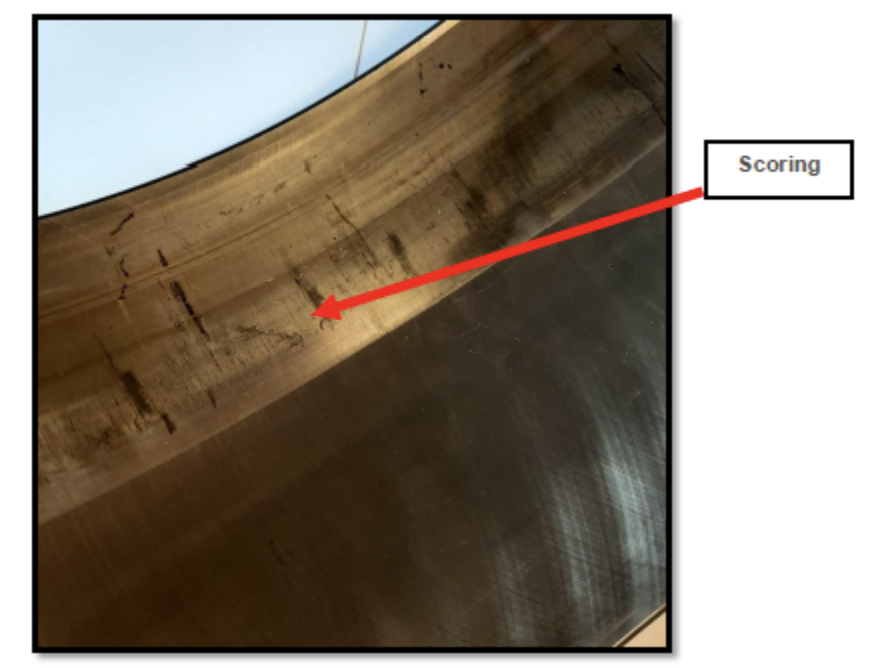

Minor damage was revealed when the bearing was sent away, as seen in the pictures below.

Image 7 Signs of scoring and smearing on part of the outer race.

Image 8 Closeup of scored outer race.

Case 2

An online pilot was installed at Coleshill Sewage Treatment Works, where DuoTech accelerometers were installed on all measuring points on the Motor NDE, DE, Gearbox Input, Output, Top and Bottom bearings for some time to prove that the system works.

The contractor who installed the screw pump installed the transducer and cable on the bottom bearing out to the Intellinova Compact unit. A special sealed connector was used as the pump is submersed in water at four meters depth.

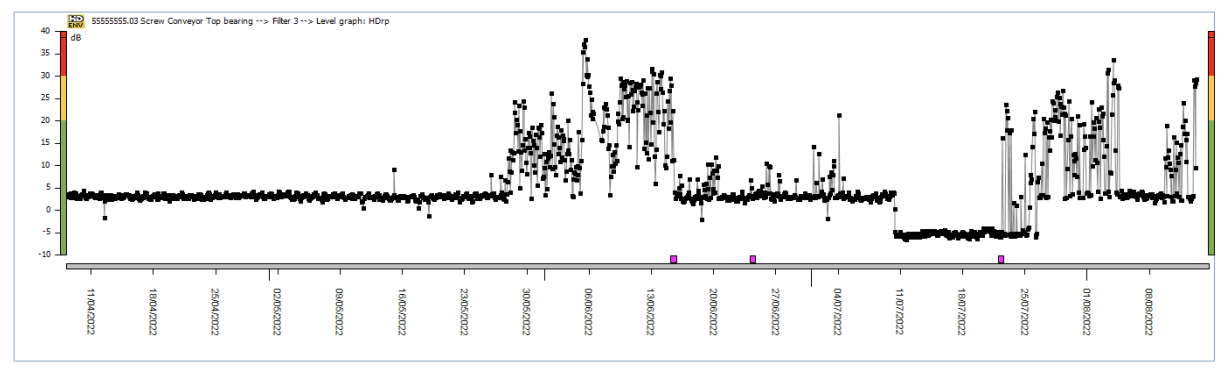

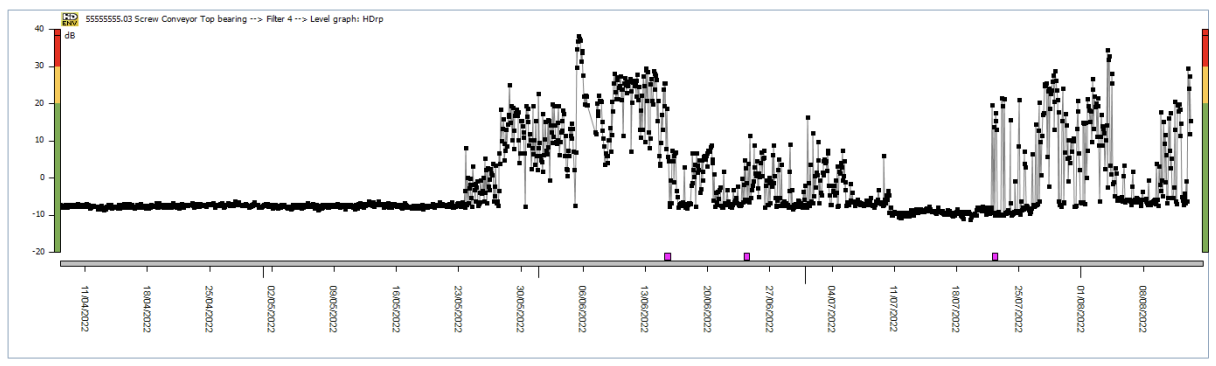

The pilot was installed in early 2022, and no changes were seen in the data until the end of May 2022. The HD ENV Filter 4 (up to 40,000 kHz) measurements initially showed the changes, followed closely by the HD ENV Filter 3, showing the presence of mature faults. The acceleration trend shown in units of COND, which shows changes over time, flatlined throughout the same period, displaying no change in amplitude.

After lubrication, the HD ENV levels dropped but kept returning to higher levels, thus indicating bearing damage. Due to the experience of the Severn Trent engineers with SPM, they concluded that this was enough proof to conclude that the pilot works.

Image 9 Acceleration trend with no significant change in amplitude over time

Image 10 HD ENV Filter 4 trend.

Image 11 HD ENV Filter 3 trend.