Condition monitoring of compressors with superior results

Taking full advantage of patented HD condition monitoring technology, SPM offers a complete, reliable, and, where needed, Ex-approved solution for monitoring the condition of compressors to optimize process efficiency and minimize downtime.

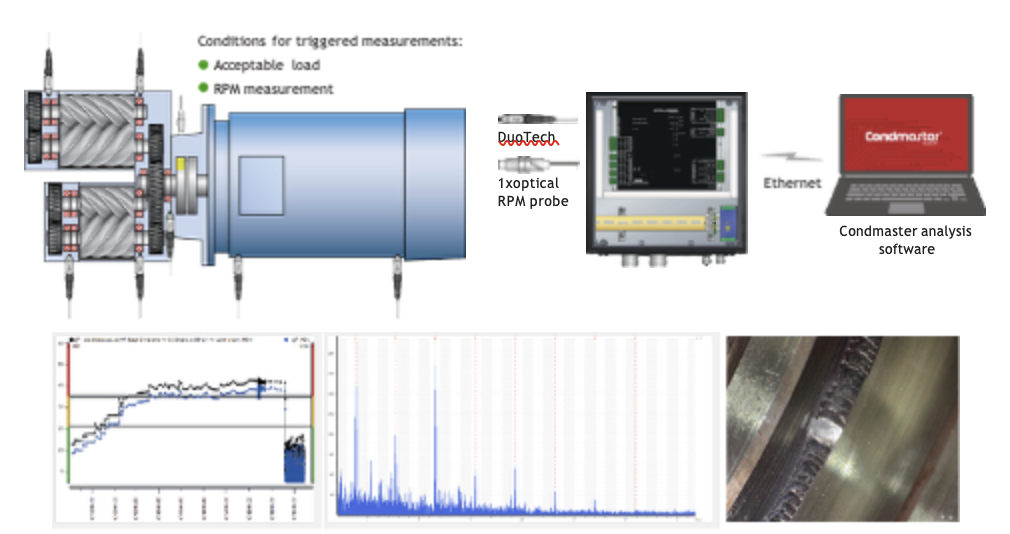

Successfully measuring the operating condition of rotary screw compressors with reliable results is a challenging task. Many parts rotating at different speeds in the same machine make it difficult to identify the origins of the measured signal. Furthermore, the compression of air generates signals that may interfere with those of individual components. Load variation and rapid speed variations during data acquisition may also be problematic because, due to resonance, measured signals may not be “linear” to the speed. Attaching a sensor in a suitable way for picking up high-frequency sig- nals can also be a challenge.

Unique possibilities with HD condition monitoring technologies

Using a high-performance online condition monitoring system and the well-proven HD technologies, we provide the technical solution required to manage these problems. In numerous successful instal- lations, vibration and shock pulse monitoring with HD technology has proven effective and reliable for screw compressor monitoring with excellent results.

HD technologies, in combination with DuoTech accelerometers, the sensitivity of which is tuned especially for measurement on rotary screws, provide an excellent toolbox for analyzing the mechan- ical condition of this kind of compressor. Thanks to the exceptional signal-to-noise ratio of the HD technologies, it is possible to distinguish between signals from each one of the compressor’s rotat- ing parts. HD Order Tracking, in combination with HDi calculation, handle the RPM fluctuations of modern, variable-speed compressors. The HDm value provides immediate condition evaluation on a green-yellow-red scale in trend graphs.

The number of measuring points depends on the compressor type. Most major manufacturers typically equip their compressors with SPM measurement adapters at the ideal sensor locations. In the case example above, the prewarning time is close to one year. The compressor is oil-free and the meas- urements are taken on the high-pressure stage. The RPM range of the rotors is between 15,000 and 24,000 RPM.

Condition monitoring with Intellinova Parallel EN

The Intellinova Parallel EN system with parallel and synchronous channels provides detailed infor- mation on the mechanical condition of components using the patented HD ENV and SPM HD meas- urement technologies. The system has a response capacity with maximum efficiency and provides razor-sharp condition data and exceptional forewarning times on developing mechanical faults.

Sophisticated digital algorithms make HD technologies less sensitive to interference from other sig- nals. Crystal clear measuring results easily understood and evaluated, make it possible to study the development of gear and bearing damages over many months.

SPM condition monitoring solutions transform high-definition measurement data into actionable information, enabling personnel to make preventive maintenance priorities for critical assets. Based on crystal-clear condition data, maintenance decisions will be well-informed and confident.

Performance, productivity, and peace of mind

Early failure detection is crucial to maximizing equipment life and performance. With fifty years of experience, SPM Instrument has the technologies, equipment, and expertise to offer efficient and flexible condition monitoring solutions for all types of industry. Through a worldwide network of resources, we provide a complete line of measurement technologies and high-performance products for industrial condition monitoring.