Introduction

This case study describes bearing damage to the felt guiding roll in the drying section of a paper machine.

The company is an Italian group founded in 1888. It now boasts a network of 52 production units operating in 132 countries with 5,000 employees.

The company’s history is deeply rooted in paper production, tracing back to master papermakers. It now excels in producing special papers across a wide range of sectors, including packaging, art, publishing, creative communication, and the adhesive materials market.

For this customer, SPM Instrument Italy performs a monthly machine check using portable instrumentation and the measuring technologies SPM LR/HR and SPM Spectrum.

Conclusion and summary

During monthly route-based measurements, condition data were acquired from the roll bearings and analyzed with the SPM LR/HR and SPM Spectrum technologies. At the time of writing, values had been trended for over fourteen years, beginning in 2008.

Over these fourteen years, lubrication was occasionally found to be poor, and the customer was recommended to re-lubricate the bearing. All the while, FFT spectrums did not show any damage.

Re-lubrication resulted in a sharp decrease in the measured SPM LR/HR values, allowing longer bearing life.

A sudden increase in SPM LR/HR values in February 2023 indicated a fault in the bearing’s inner race, and the customer was recommended to replace it. After dismounting the bearing, visual inspection confirmed the inner race damage.

Thanks to the SPM LR/HR technology’s capacity to detect poor lubrication conditions, bearing life was significantly increased. This enabled the customer to continue running the machine for a longer time without interruptions due to unplanned downtime. The bearing lasted fourteen years thanks to precision lubrication enabled through the SPM LR/HR technology.

Using portable instrumentation to measure these applications, fault prewarning times are typically six weeks. They can be longer where online systems are used.

Application description

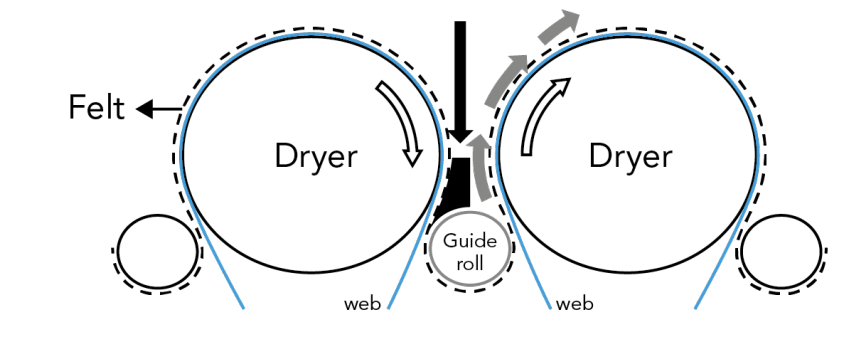

Paper rolls are used to guide the product through the process. They are driven by an electric motor and are several meters wide. Guide rolls are used to guide the felt involved in the paper drying in the machine’s drying section. These rolls are critical to the process.

Data was acquired manually with a Leonova Diamond handheld instrument.

Figure 1 Drawing of the machine’s felt guide roll.

System setup

Measuring equipment

The handheld Leonova Diamond instrument with a TRA78 shock pulse transducer was used to perform the measurements.

The actual roll running speed is supplied by the customer through their automation system and given to the SPM technician at the moment of the measurement.

The customer’s goal is to use SPM condition monitoring technologies to find bearing damage at an early stage to avoid unplanned machine downtime.

Measurement technologies

Different techniques have been used to detect bearing damage at various stages of damage development. The SPM LR/HR combined with SPM Spectrum has been used to monitor lubrication effectiveness and bearing damages.

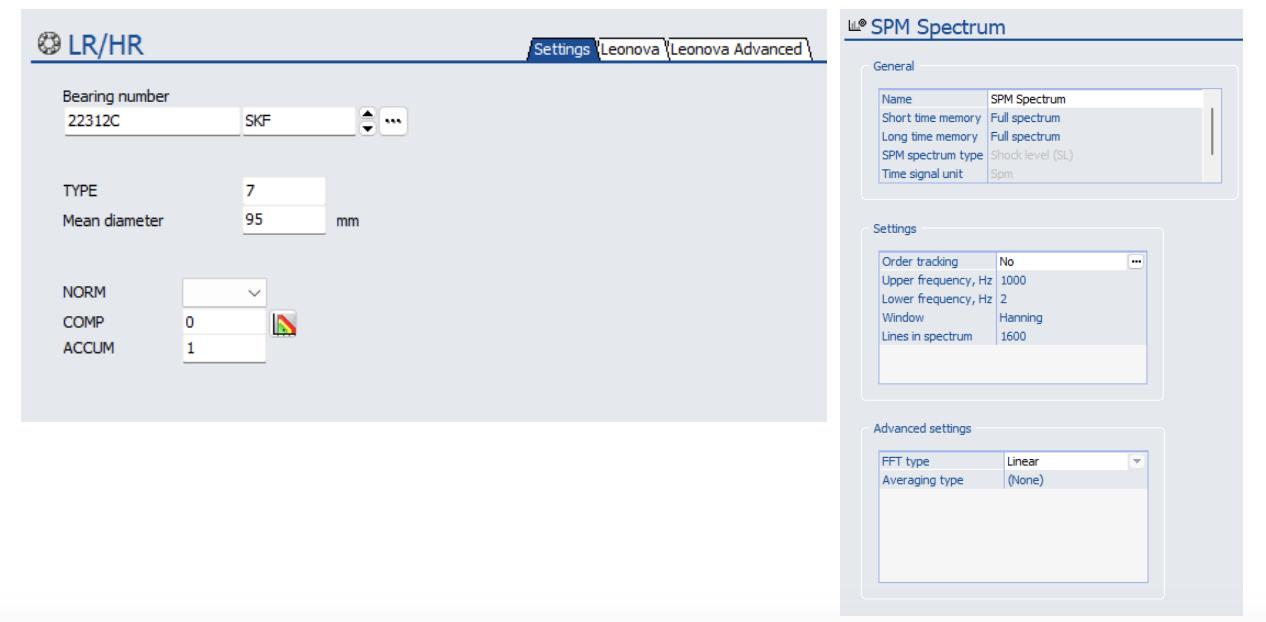

Condmaster setup

The configuration of measuring assignments is as follows:

Image 1 Settings in the Condmaster analysis and diagnostic software.

Case description

Measurements were started in 2008 and have since been carried out every 1-2 months.

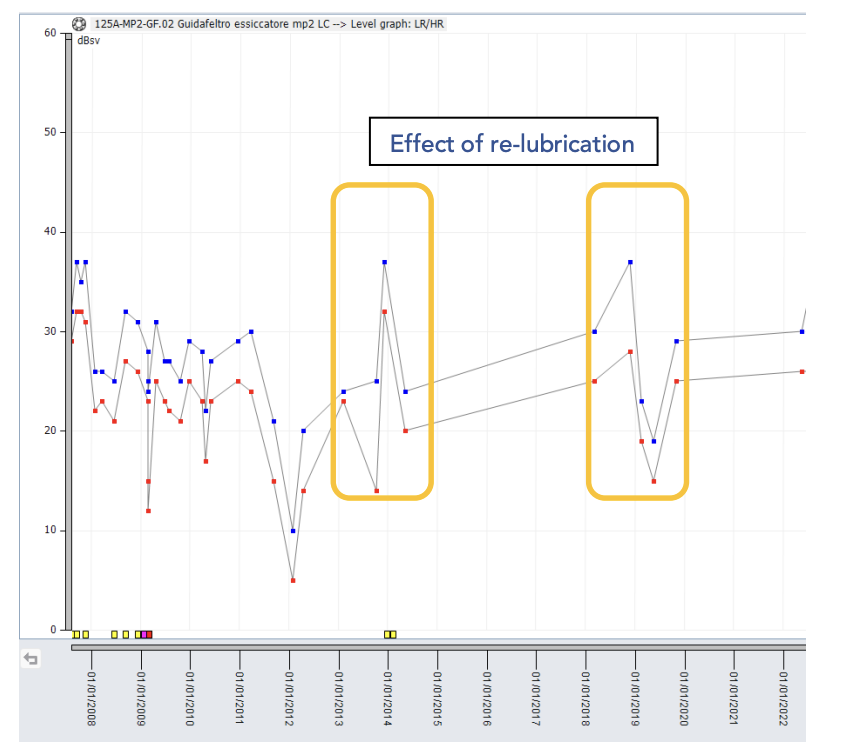

The SPM measuring results indicated poor lubrication, which was solved by re-lubrication actions. The trend graph below shows how the values decrease after lubrication activities.

Image 2 The SPM LR/HR trend. However, some time after each lubrication, the dBsv levels start to rise again, indicating bearing damage.

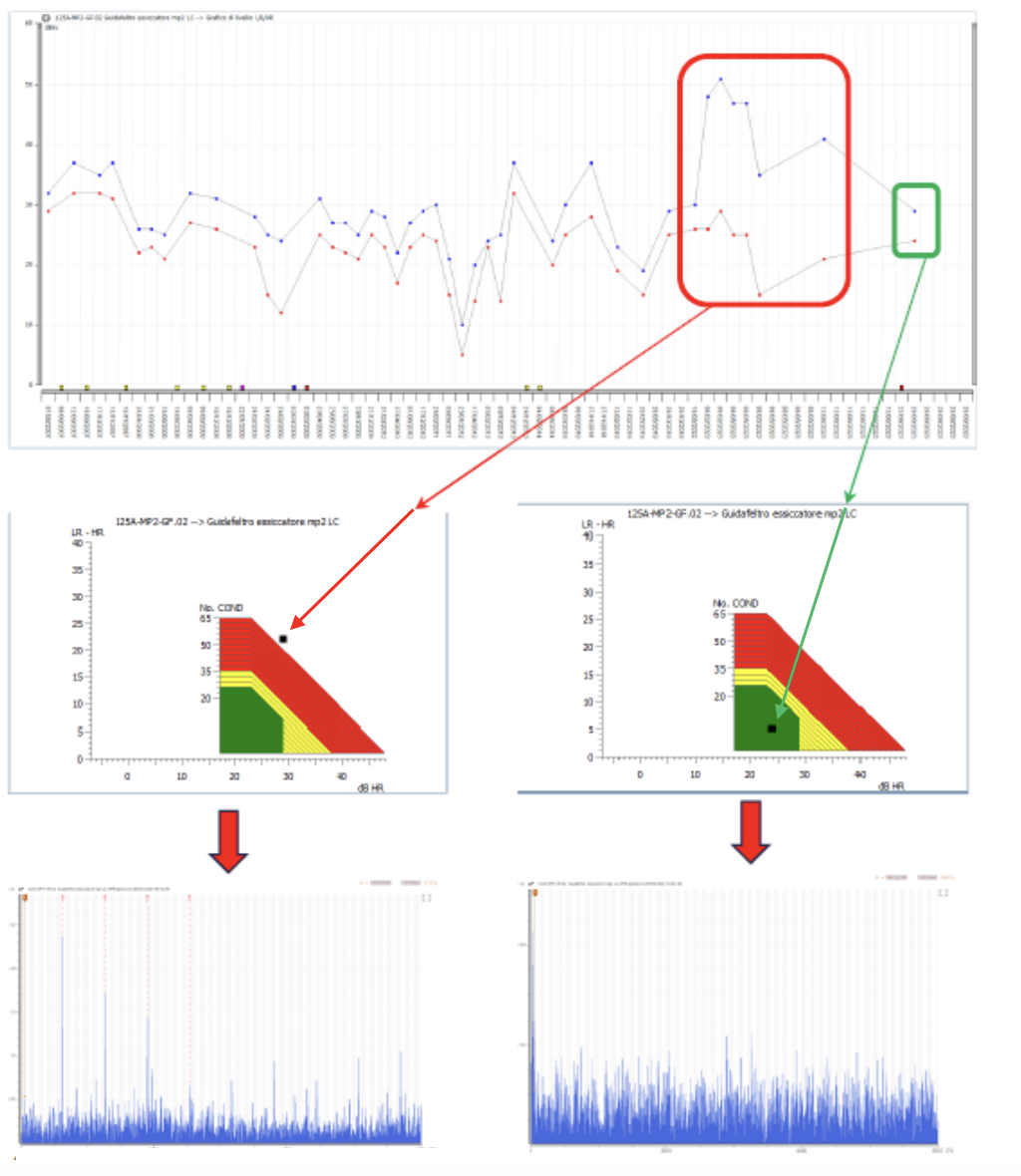

A sudden and rapid change in the SPM LR/HR trend suggested the possibility of bearing damage. The Lubmaster graph and SPM Spectrum showed inner race harmonics at the BPFI frequency.

The bearing was inspected and replaced, and measurements after the bearing replacement showed decreasing values.

Image 4 SPM LR/HR trends, Lubmaster graphs, and spectrums.

Image 5 The bearing inner race damage.

Conclusions

Due to the high efficiency of the SPM condition monitoring technologies, the customer was able to extend the life of the guide roll bearing through precision lubrication.

The ability to detect lubrication defects for over fourteen years without downtime proved the technologies’ capacity for prewarning time and reliability to the customer.

Fault prewarning times with portable instrumentation are shown to be four to six weeks (and can be even longer with online systems).