Profitable vibration monitoring solution for pumps

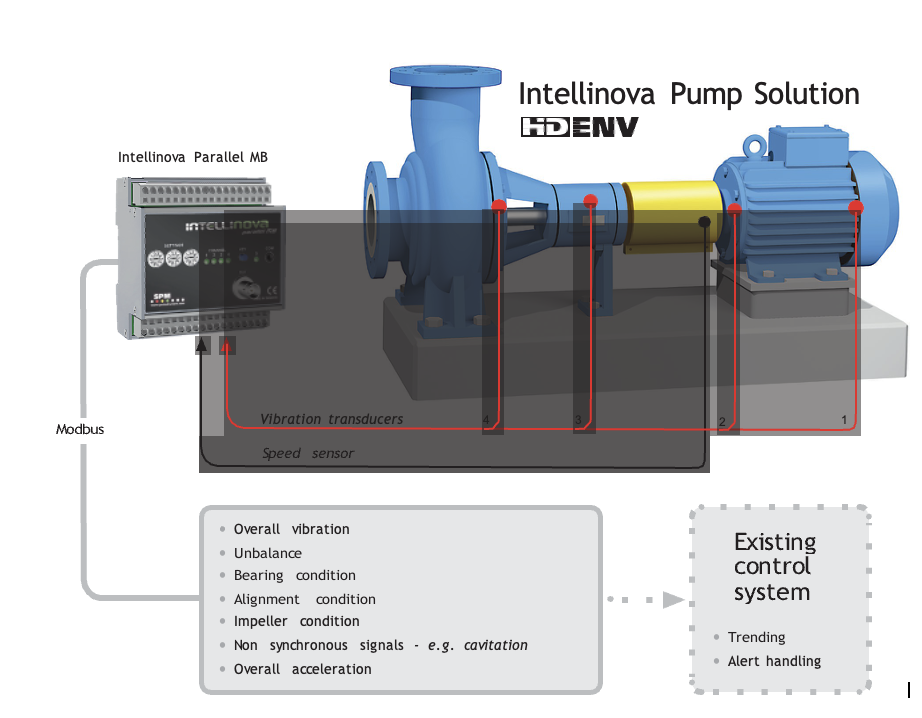

One of the most fundamental industry applications is the motor-pump assembly. To increase pump operating efficiency, minimize unplanned downtime and reduce operating costs, the Intellinova monito- ring solution for pumps offers reliable vibration monitoring tied into existing monitoring and control systems.

Many pump problems and failures manifest themselves as vibrations, and keeping an eye on vibra- tion levels, therefore, is a profitable strategy. Without requiring an extensive vibration monitoring program, the solution efficiently monitors failure symptoms such as unbalance, impeller condition, or bearing wear. Vibration measurement is done with HD ENV®, a High Definition monitoring tech- nology delivering high-precision data relevant to the failure modes of interest. The method enables the detection of gear and bearing faults very early on in the damage process, making it possible to closely monitor the development.

With a single monitoring unit, the solution integrates seamlessly with control and asset management systems via Modbus RTU. In a typical motor-pump assembly, the unit measures vibration levels on four positions in parallel, delivering readings to control systems with minimum latency. The readings transferred from the monitoring unit reflect the current condition of the equipment. The condition information is handled in the control system, which can trigger alerts if pre-set alert levels are exceed- ed and – if needed – request a spectrum or time signal for detailed analysis. In order to prevent false alerts due to occasional high readings, the pump solution implements an algorithm which handles fluctuating readings not attributed to mechanical problems.

Easy to install and configure, the Intellinova monitoring solution for pumps provides reliable and timely information to facilitate troubleshooting, diagnosis, and repairs. Providing ample forewarning, the solution maximizes the planning horizon for predictive maintenance measures when abnormal or increasing vibration levels are indicated.

The pump monitoring solution

Installation is straightforward. Standard IEPE vibration transducers are installed on the volute and on each of the bearings. A speed sensor is used in order to extract accurate failure symptoms. Ruggedly designed transducers with cable protection conduits ensure a mechanically robust installation.

Vibration signals are transferred from the transducers to an Intellinova Parallel MB unit nearby. The monitoring unit is programmed to deliver a scalar value per failure symptom, corresponding to the amplitude of the signal.

The principles of the solution are the same for all kinds of pumps and irrespective of mounting direction.

Performance, productivity, and peace of mind

Early failure detection is crucial to maximizing equipment life and performance. With fifty years of experience, SPM Instrument has the technologies, equipment, and expertise to offer efficient and flexible condition monitoring solutions for all types of industry. Through a worldwide network of resources, we provide a complete line of measurement technologies and high-performance products for industrial condition monitoring.