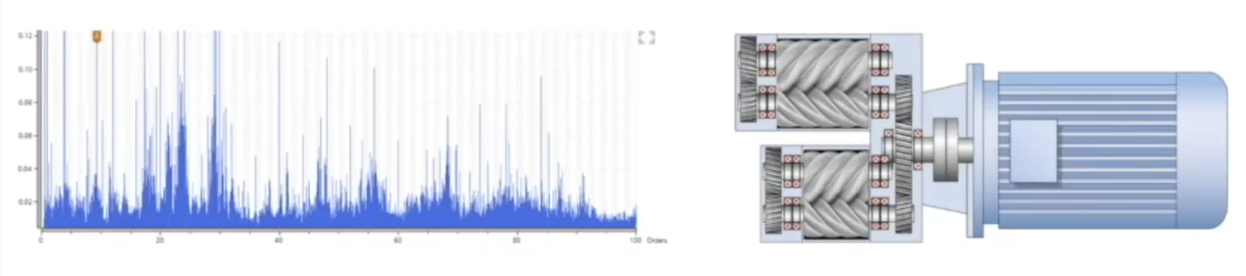

Traditionally, when you perform condition monitoring on rotary screw compressors, the spectrum looks messy because there are many signals generated from many rotating parts.

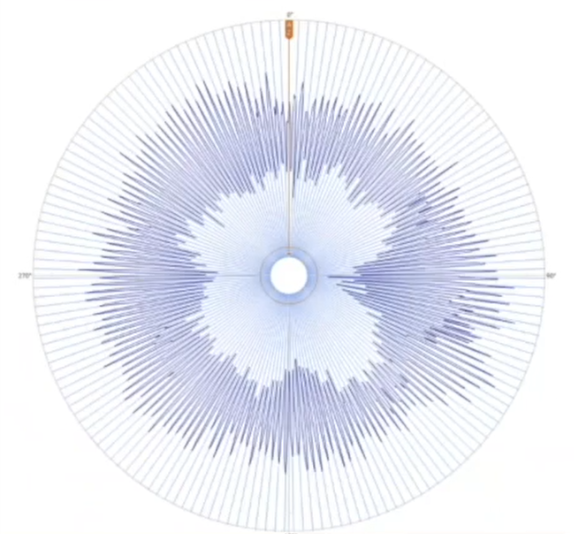

Figure 1: Traditional signal pattern on rotary screw compressors

In the case of the rotary screw compressor in Figure 1, there are five rotating parts—a lot of gears and bearings and also signals generated by the compression of air. In addition to that, there may be other factors such as load/unload condition and variable speed.

Performing condition monitoring on rotary screw compressors can be tricky, but the combination of HD technologies and DuoTech transducers provides a good toolbox for this analysis.

The HD technologies we use at SPM are SPM HD, HD ENV, HD Order Tracking, and functions and features such as pseudo tachometer, time synchronous averaging, and time synchronous averaging in combination with pseudo tachometer and HD Order Tracking.

The DuoTech accelerometer is a combination of a Shock Pulse transducer and a vibration transducer, so you can use it for Shock Pulse measurements and also for vibration analysis.

Figure 2: DuoTech accelerometer

We have a special version of the DuoTech accelerometer that is specially designed for measuring rotary screw compressors and can handle the very high signal levels that these machines emit.

One advantage of HD technology is the ability to pick up signals from different parts of the compressor. You can use functions and features to obtain discrete signals from the bull gear and its bearings, the male rotor through the low-pressure element, the female rotor through the low-pressure element, and the same components through the high-pressure elements.

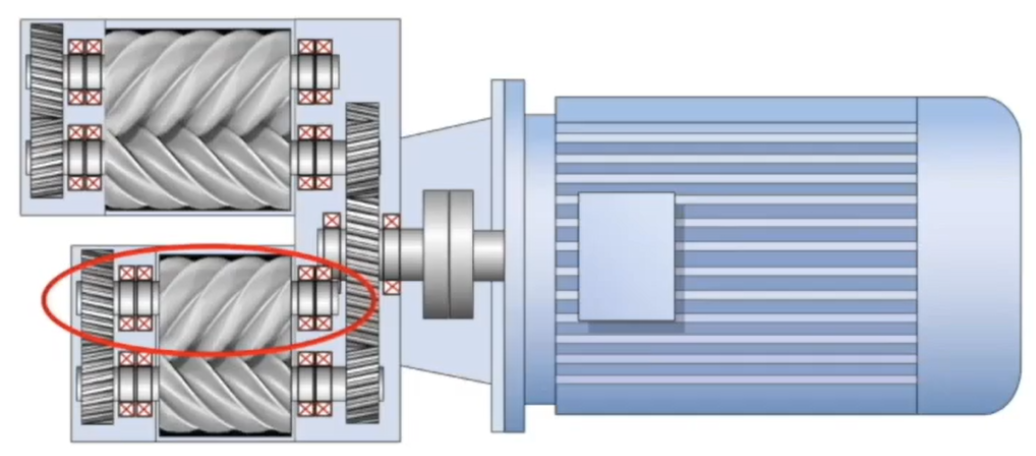

Figure 3: Obtaining discrete signals from each part of the compressor

One of the fundamental principles of HD technology is that you set up the system to look at different parts of the compressor. Very often, you will not find any faults, and you will see that everything is working well in the compressor.

For example, if you want to look at the bull gear to check for gear faults, you would use time synchronous averaging, meaning that you average out all of the signal that is not synchronous with the RPM.

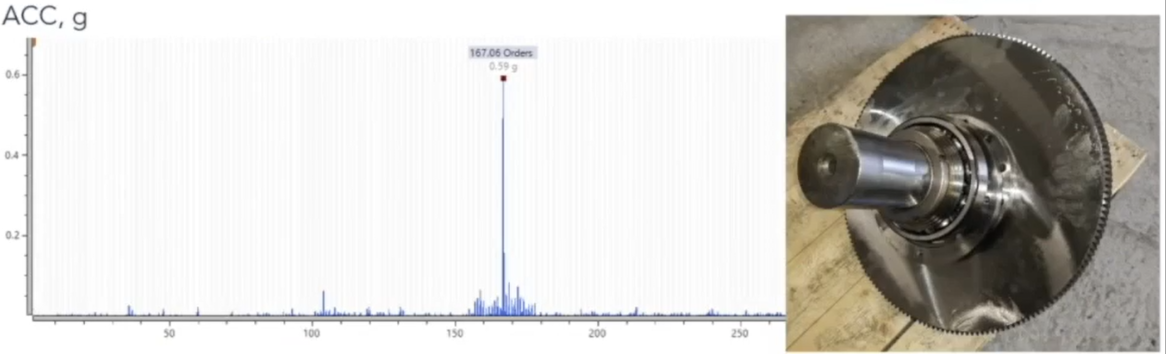

Figure 4: Bull gear with acceleration spectrum

If you look at the acceleration spectrum, in this case, you will see a peak at 167 times the running speed. And if you were to count the teeth on the bull gear, you would find that it has exactly 167 teeth.

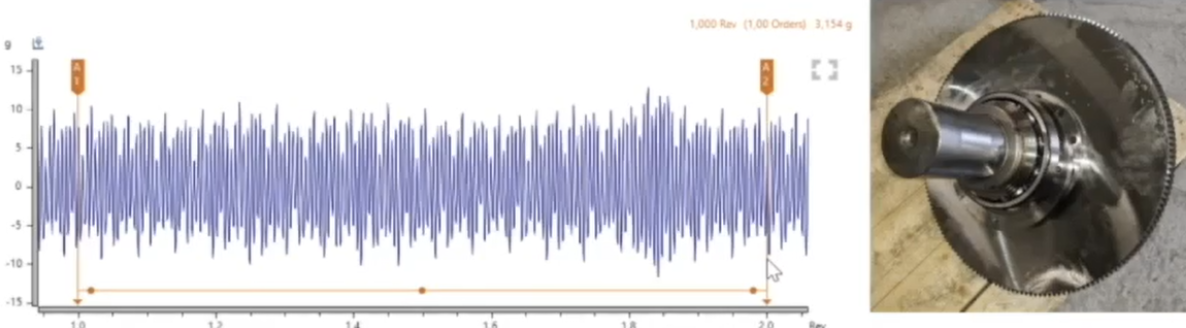

Another way of looking at the signal from the bull gear is to look at the time domain. The time signal shown in Figure 5 represents one revolution of the bull gear.

Figure 5: Bull gear with time domain

If you were to connect the beginning of the time signal with the end, it would form a circular plot representing the time signal of one revolution of the bull gear. Each signal is generated by one tooth of the bull gear.

Figure 6: A circular plot shows the signals generated by every tooth of the bull gear

If you were to count the peaks, there would be 167. This is a helpful way of viewing the condition of a bull gear, or any gear.

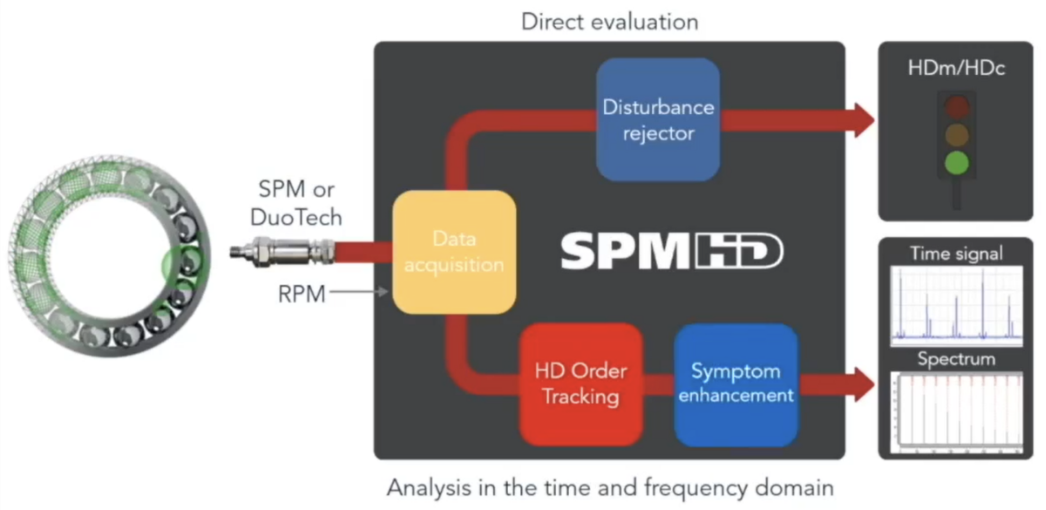

The most common problem with rotary screw compressors is bearing faults. We use SPM HD to assess the bearing condition and find faults. You can use either a short-pass transducer or a DuoTech transducer. Most of the time, you also measure the RPM.

When you measure HDm or HDc, you will see green, yellow, or red, directly representing the condition of the bearing. An algorithm reduces the disturbances, so it is called a disturbance rejector.

Figure 7: Using SPM HD to measure a bearing

The HDm measurement represents the bearing faults while HDc represents the lubrication condition. If you have a high Shock Pulse reading, you can check the time and frequency domain for the type of fault you have.

We also use HD Order Tracking to keep track of the RPM fluctuations during data acquisition, and symptom enhancement to enhance repetitive signals.

All of this results in clear time signals and spectrums.