- Description

- Additional Information

- Benefits

- Features

- Technical Overview

- Instrument Modules

- Downloads

Description

Leonova Diamond® – Unique Condition Monitoring Efficiency

Leonova Diamond® is a powerful portable instrument built for reliable condition measurement in rough industrial environments. Ideal wherever measuring route efficiency is a priority, it combines proven measuring techniques and advanced diagnostics in one robust device. With a full range of sophisticated measurement methods and built-in troubleshooting capabilities, Leonova Diamond efficiently handles varying machine characteristics and operating conditions. State-of-the-art digital technology and carefully designed software ensure superior data acquisition and processing, while an intrinsically safe version is available for hazardous areas.

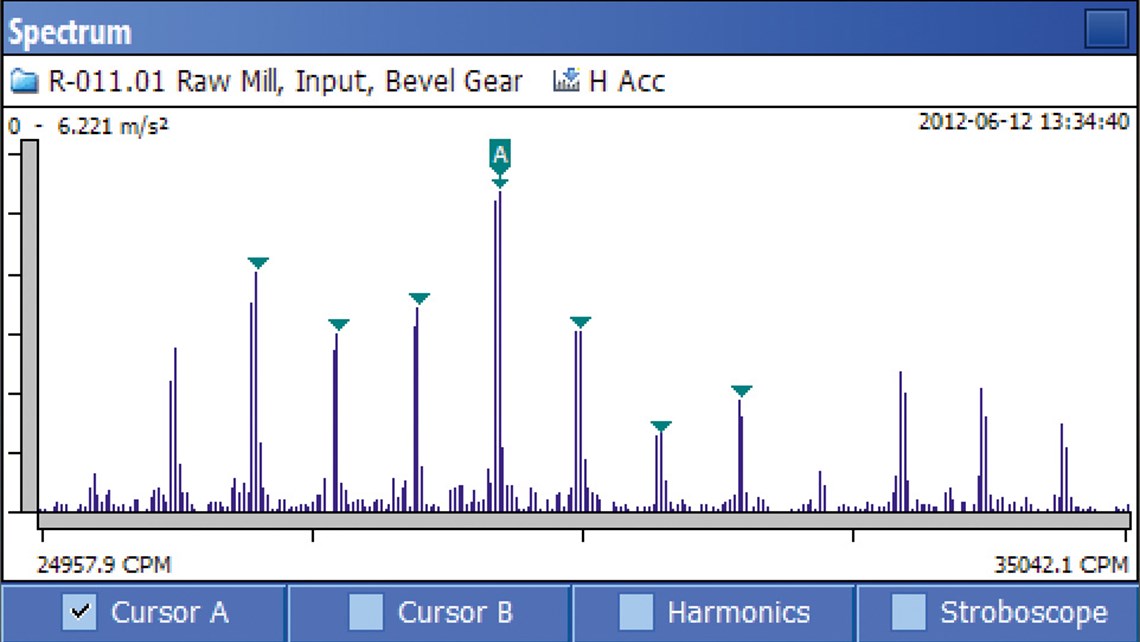

Using patented HD technologies, Leonova Diamond delivers highly accurate vibration and shock pulse measurements, producing razor-sharp spectrums even when signals are weak or masked by stronger ones — a decisive advantage for complex machinery such as gearboxes. Part of the Leonova line of portable instruments and sibling to Leonova Emerald®, it offers maximum monitoring performance and reliability in a single, rugged solution.

Additional Information

| Specifications | Leonova Diamond Advanced, Leonova Diamond Basic, Leonova Diamond Expert |

|---|

Benefits

THE DIFFERENCE IS IN THE DATA

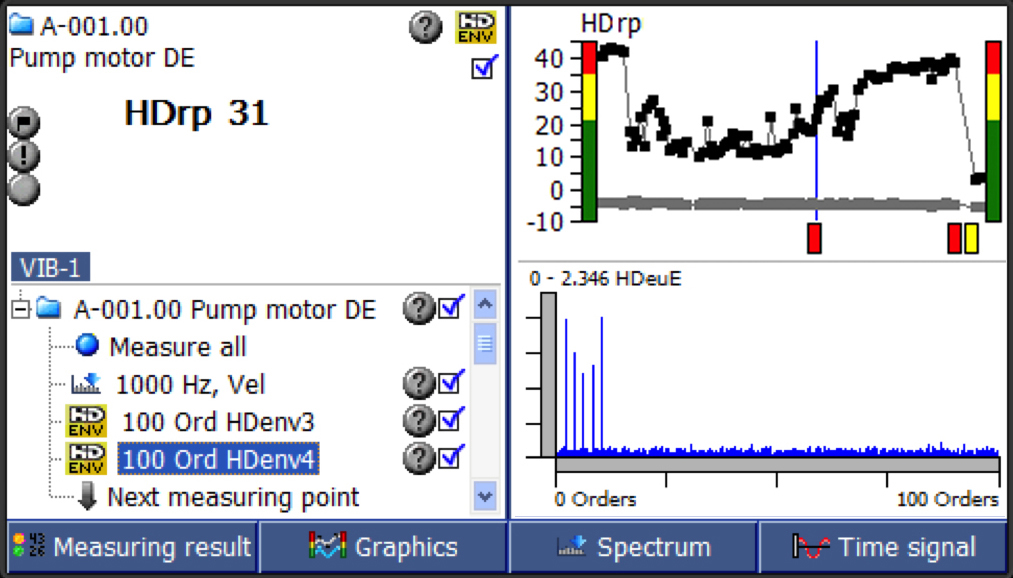

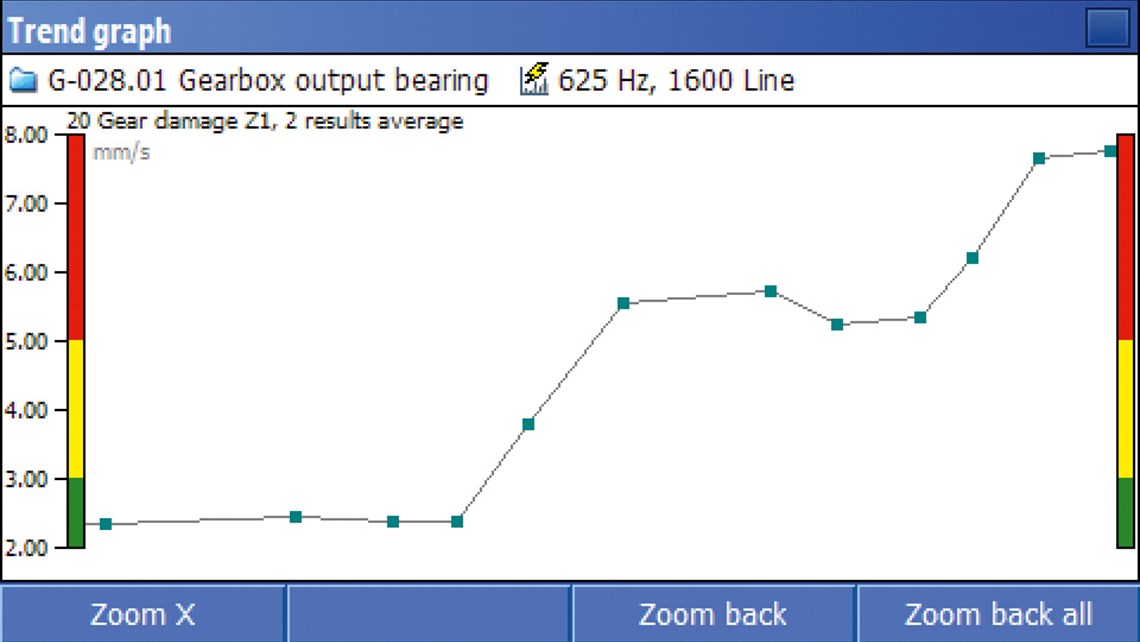

With the patented HD condition monitoring technologies, detecting gear and bearing faults at a very early stage and pinpointing the source has never been easier – or more efficient.

ENGINEERED FOR PERFORMANCE

Measurements are more precise and spectrums more detailed than ever before, making in-depth bearing and vibration analysis possible even on the most complex industrial applications.

PRODUCTIVITY AND EFFICIENCY

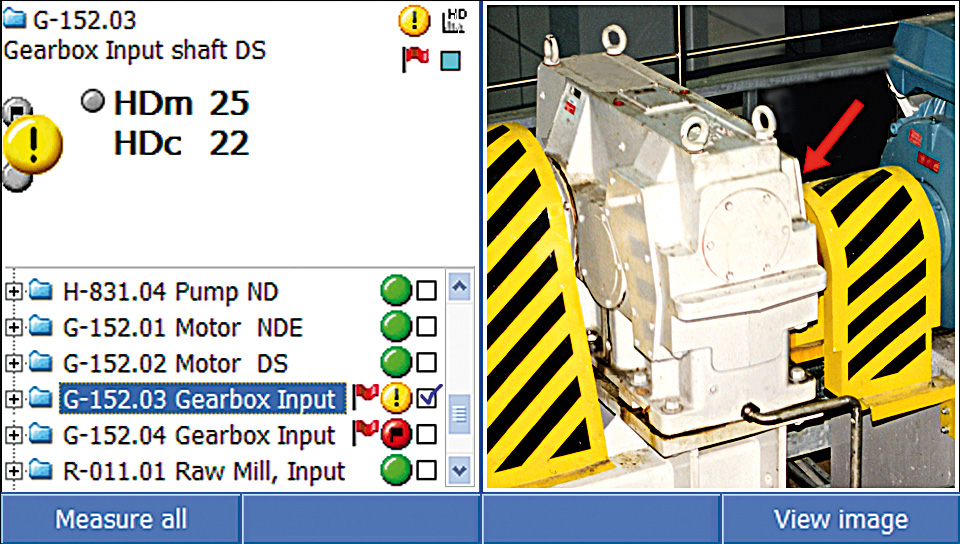

Multiple measuring assignments can be carried out with the push of a single button. Immediate condition evaluation, alarm generation, historical data, and trends – all delivered right on the screen.

Features

Leonova Diamond includes High Definition Shock Pulse Method (SPM HD®) for bearing condition and advanced three-channel vibration analysis for general machine condition and many more features, see below.

Bearing and lubrication condition

Note: Also read about HD ENV® (below) for bearing monitoring.

The SPM HD® method (HDm/HDc)

SPM Spectrum™

dBm/dBc

The original Shock Pulse Method is based on dBm/dBc that counts the rate of incoming shock pulses per second and provides one value for the shock carpet level and one value for the maximum level (peaks).

LR/HR

The LR/HR method was developed from the original Shock Pulse Method for condition diagnosis of rolling element bearings and allows a precision analysis of oil film condition in the rolling interface.

Vibration analysis

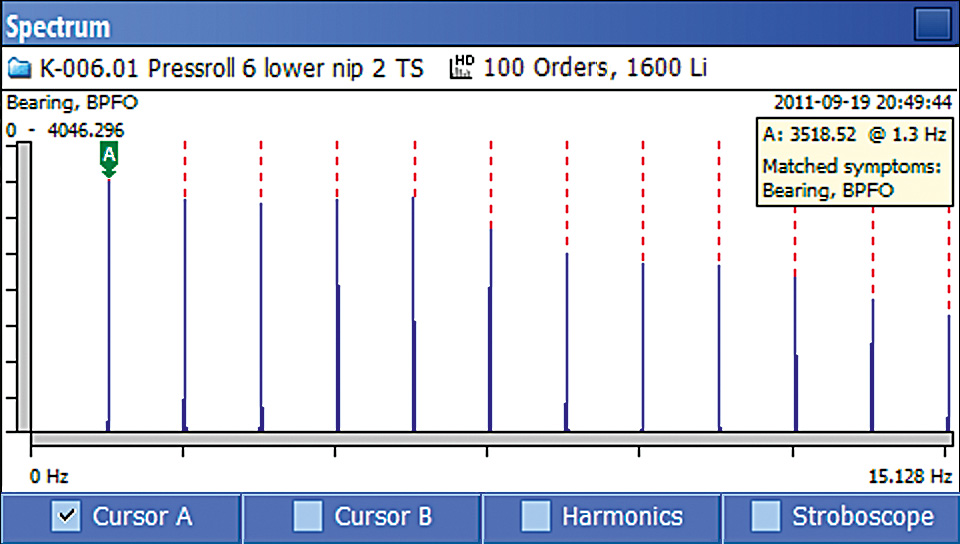

The HD ENV® technique

HD ENV® is a patented enveloping technique used for early detection of impact-related events such as gear and bearing damage. A number of predefined filters are available for easy selection; each designed to detect damages in different failure stages. The method utilizes cleverly engineered algorithms for digital signal processing to obtain optimal data for trending purposes.

Vibration severity plus FFT Spectrum

Measurement of vibration velocity, acceleration, and displacement (0-40kHz frequency range) according to the latest ISO 10816 standards helps to diagnose general machine condition. In addition to the RMS vibration readings, the instrument displays an FFT spectrum, where symptoms of imbalance, misalignment, and structural weakness are easily identified.

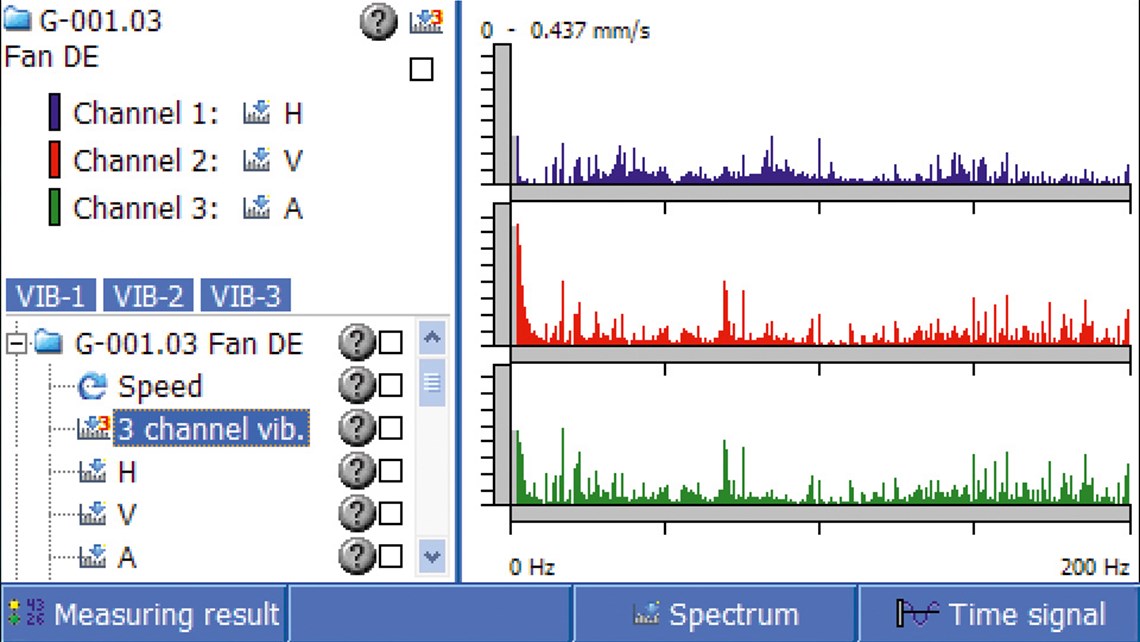

Three-channel vibration analysis

Three-channel vibration measurement allows you to study machine movement in three dimensions by observing the difference of the phase angles measured on the three channels. The three channels measure simultaneously, which means fast operation and rapid evaluation of assignments.

EVAM

The EVAM (Evaluated Vibration Analysis Method) measuring technique produces up to 25600 line spectrum with true zoom, provides ready-made machine 'fault symptoms' as well as trending.

Journal bearings

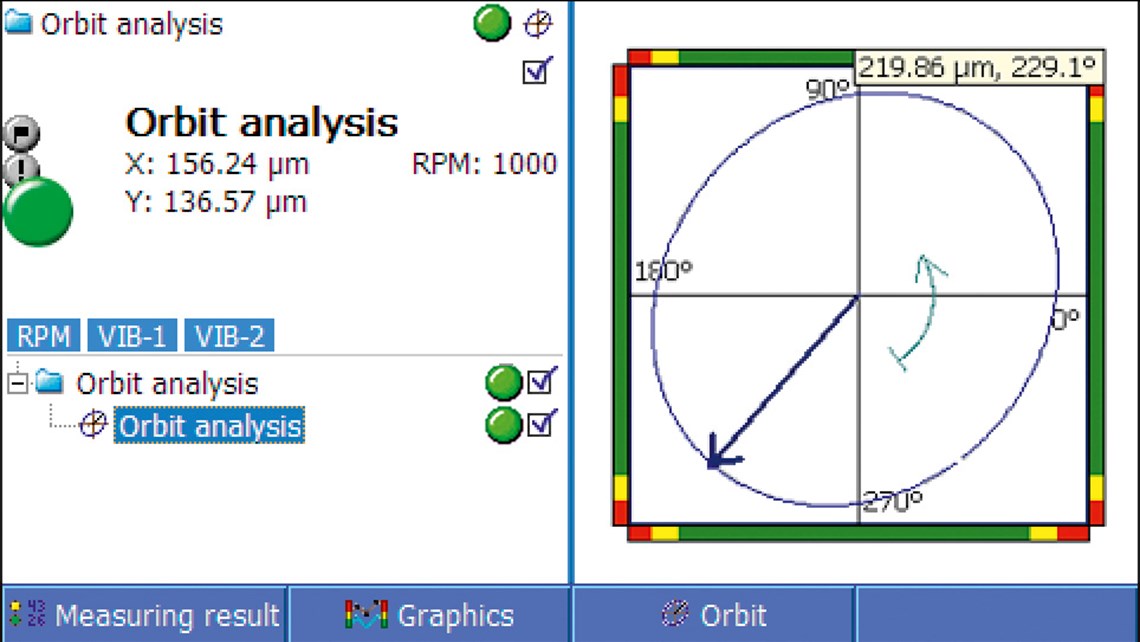

Orbit analysis

For all machines with journal bearings, simultaneous measurement with two vibration transducers supplies an accurate graph of the shaft centre line movement.

Resonance

Structural resonances

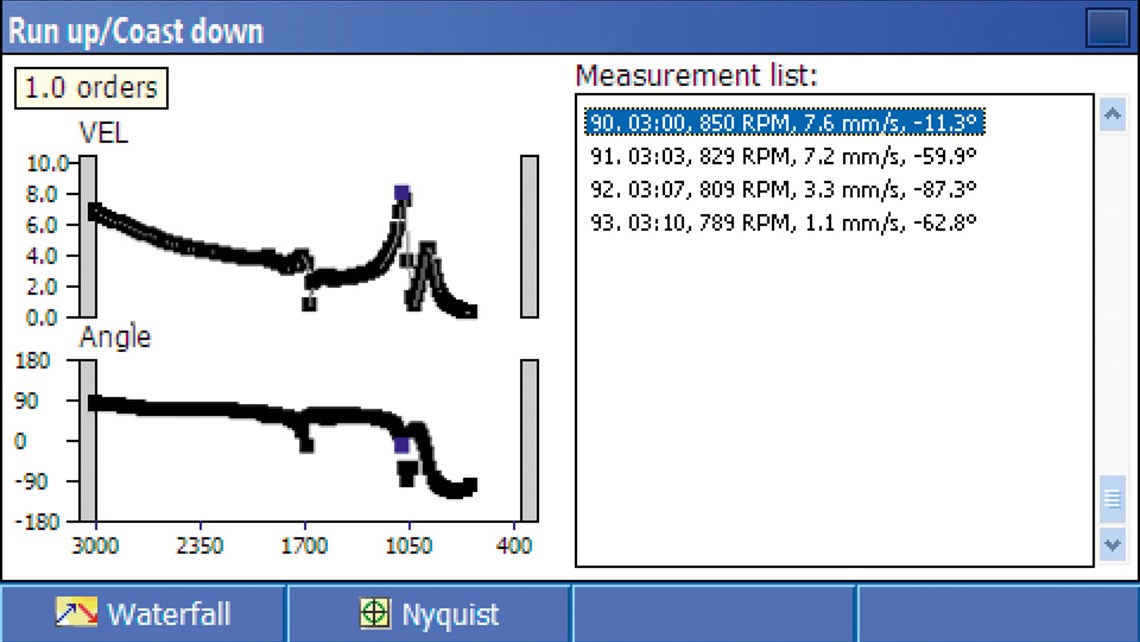

Run up/Coast down measurement and Bump test are tools for root cause analysis and show the machine frame vibration characteristics, resonance frequencies, and the reaction at critical speeds.

Corrective maintenance

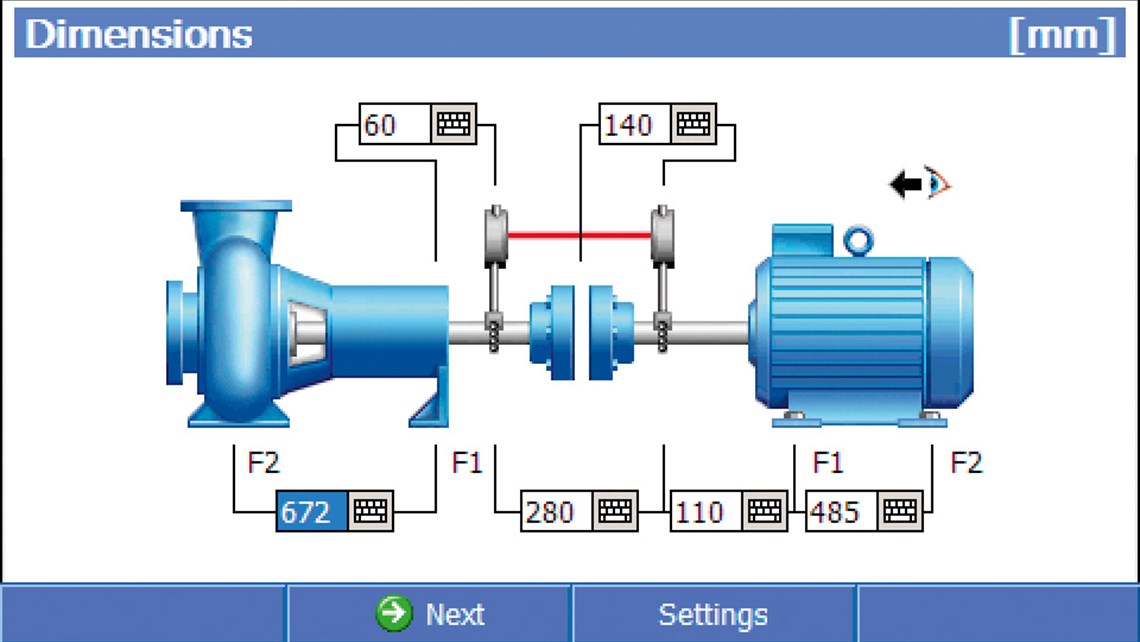

Precision shaft alignment

For laser alignment of horizontal and vertical machines, the optional LineLazer Alignment Kit connects wirelessly to Leonova Diamond, and the user is guided through the alignment procedure to a perfect result.

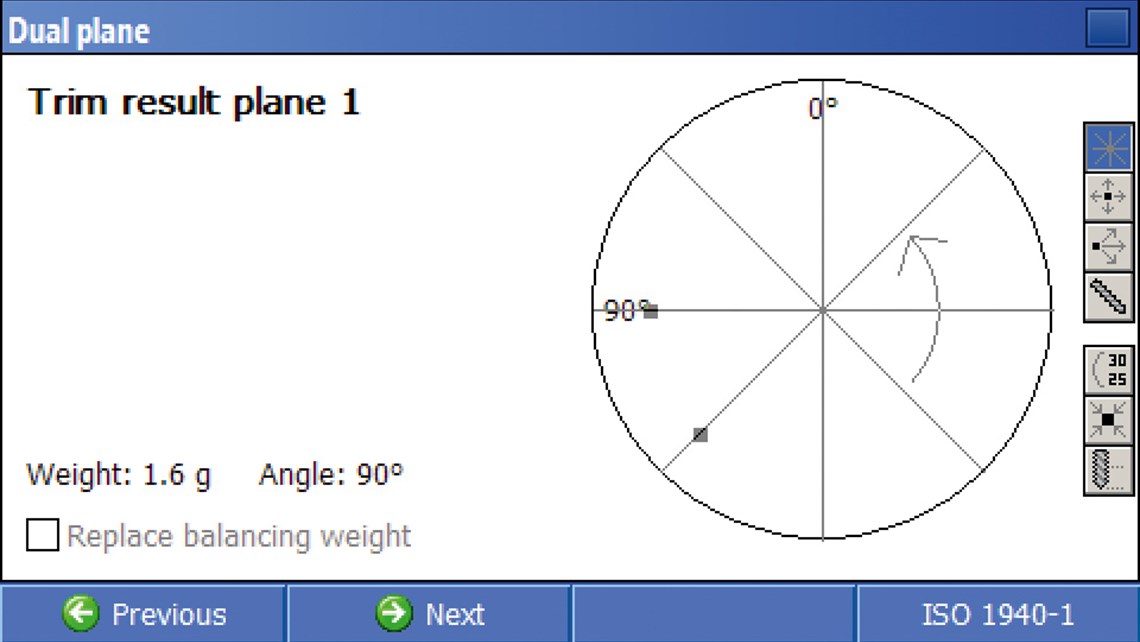

Dynamic balancing

Field rotor balancing in single and dual plane according to ISO 1940-1 standard with an initial vibration measurement guiding the user through a balancing procedure with suggestions for correcting the imbalance.

HD Order Tracking

On machinery operating under variable speed, vibration analysis with HD Order Tracking provides reliable data and crystal clear measuring results even when RPM varies greatly during the course of measurement. Order Tracking is applicable in a very wide RPM range, from just a few to thousands of revolutions per minute.

Technical Overview

Instrument

Dimensions: 297x130x69 mm

Weight: 890 g

Display: TFT colour, 480x272 pixels, 4.3-inch widescreen, adjustable backlight

Instrument Modules

Platform always included for unlimited use

- Platform function: SPM HDm/HDc and/or SPM LR/HR.

- RMS vibration, ISO 2372.

- Speed measurement.

- Temperature measurement.

- Stethoscope function.

- Analog signals, current, and voltage.

- Time signal recording.

- Measuring point identification with CondID® memory tags.

- Automatic recording, up to 50 hours.

- Checkpoints, free text.

- Recording of vocal comments.

- Supports 2 channel simultaneous vibration measurements.

- Supports up to 12 800 lines, 20 kHz.

Functions for unlimited or limited use

Unlimited and limited functions can be combined at will.

- SPM HD Expert, time, and frequency domain analysis.

- Shock pulse method HDm/HDc.

- Shock pulse method dBm/dBc.

- Shock pulse method LR/HR.

- SPM Spectrum.

- Vibration ISO 10816 with spectrum.

- Vibration ISO 20283-5.

- Orbit analysis/Shaft centerline plot.

- 3 channel simultaneous vibration.

- Vibration Expert.

HD Order Tracking.

Time signal and 25 600 lines/40kHz.

HD ENV.

EVAM evaluated vibration analysis.

Post trigger.

Run up/coast down.

Bump test.

Frequency Response Function (FRF). - Vibration Advanced.

HD Order Tracking.

Time signal and 12 800 lines/20kHz.

HD ENV.

FFT spectrum with symptoms.

Post trigger. - HD Analysis.

Vibration Expert.

SPM HD Expert. - Balancing, single, and dual plane.

- Shaft alignment.

Related Products